Description.

The magneto is of rotating armature pattern, and is fitted with an automatic timing control. The latter employs a driving gear carrying a plate fitted with two pins; a weight is pivoted on each pin and the movement of the weight is controlled by a spring connected between the pivot of the weight and a toggle lever pivoted at approximately the centre of the weight. (Fig. 16).

Holes are provided in each toggle lever, which locate with pegs on the underside of a driving plate secured to the magneto spindle. This plate is also provided with stops that limit the range of control.

When the magneto is stationary, the weights are in the closed position and the magneto retarded for starting. When the engine is started and the speed is increased, centrifugal force acting on the weights overcomes the restraint of the springs and the weights move outwards, causing relative movement between the driving gear and the magneto spindle, so advancing the ignition timing.

The characteristics of the control are arranged to conform closely with the engine requirements.

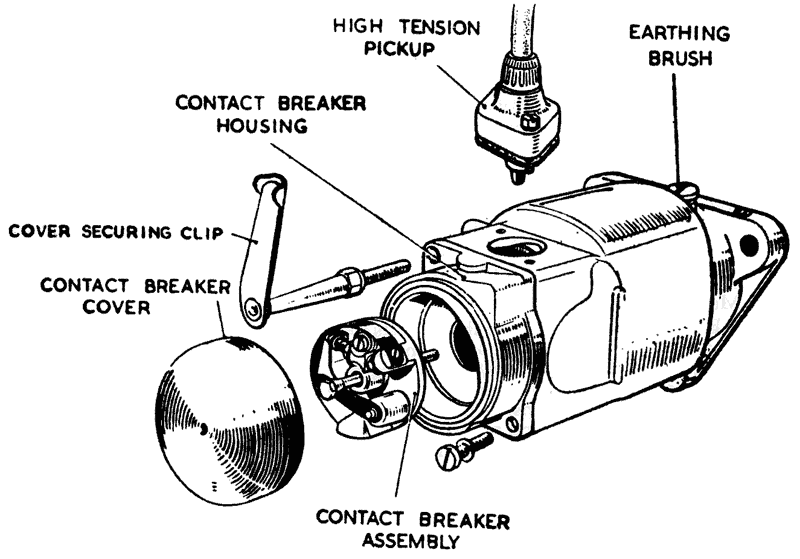

Features of the magneto include a ring cam operated contact breaker, and a high energy magnet cast integral with the magneto body.

The armature ball bearings which are packed with grease during assembly, will not need attention until the motor cycle is dismantled for a general overhaul, when it is advisable to have the magneto inspected at a Lucas Service Depot, or by a Lucas Agent.

Maintenance: Lubrication.

Every 3.000 miles take out the hexagon-headed screw from the centre of the contact breaker (Fig. 40) and pull the mechanism off the tapered shaft to which it is fitted. Push aside the rocker arm retaining spring, loosen the two small screws to free the spring—prise the rocker armn off its pivot and smear the bearing lightly with clean engine oil.

The cam is lubricated from a felt pad contained in a pocket in the contact breaker housing. A small hole in the cam is fitted with a wick that allows the oil to reach the surface of the cam. Add a few drops of thin oil (SAE10) to the wick. Do not allow any oil to get on the contacts.

When refitting the contact breaker be sure that the projecting key on the tapered part of the contact breaker base engages with the keyway cut in the magneto spindle, otherwise the timing will be upset.

Tighten the hexagon headed screw carefully. It must not be slack but no undue force must be used. Check the contact point gap : see below.

Maintenance. Adjustment.

Every 3,000 miles check the contact point gap, after turning the engine until the contacts are fully opened. The correct gap is 0.012"-0.015" (0.305 - 0.381mm). If the setting is correct, the .012-in. gauge will be a sliding fit between the contacts, but if too tight or too loose the gap must be adjusted.

Contact Breaker Adjustment.

To adjust keep the contact breaker in the position giving the maximum opening of the contacts. The fixed contact plate is secured by a single screw passing through a slotted hole in the plate. To adjust the contact breaker gap. turn the engine until a position of maximum contact separation is reached, slacken the screw and, using a screwdriver, adjust the gap to 0-012"-0-015” (0-305—0-381 mm.) Tighten the screw and check the setting. A flat steel guage of appropriate thickness should be a sliding fit between the contacts.

Maintenance. Cleaning.

Every 6,000 miles examine the contacts for signs of burining or blackening. Clean them with a fine carborundum stone, or with a superfine emery cloth. Wipe away all dust and dirt afterwards with a petrol-moistened cloth.

It is easier to attend to the contacts if the contact breaker is removed.

Remove the high tension pick-up—held to the magneto body by two screws—wipe it clean and polish with a fine dry cloth. The pick up brush must move freely in the holder. If it is dirty, clean with a petrol-moistened cloth. Should the brush be worn to within 1/8-in. of the shoulder it must be renewed.

While the pickup is removed. clean the slip ring track and flanges by holding a soft cloth against the ring with a wedge of wood suitably shaped to conform to the included angle of the slip ring flanges, and turn the engine slowly. Remove the rag, and repeat the cleaning with another piece until all dirt is cleaned from the slip ring.

Testing the Magneto for Causes of Misfiring, or Failure of Ignition.

Disconnect the high tension cable from the sparking plug and hold it so that the terminal end is about 1/8-in. from some metal part of the engine such as the edge of one of the fins on cylinder or head.

(1) Rotate the engine smartly by means of the kick-start and note the spark that jumps from the terminal to the engine. If the spark is strong and regular the fault lies with the sparking plug which should be removed for inspection and attention.

(2) Examine the high-tension cable. After long service or if oil has been allowed to get on to and remain on it, the insulation may have become perished or cracked. If so fit a new one.

(3) lf the magneto has been replaced recently or removed and refitted it may be incorrectly timed. Refer to page 46 for timing instructions.

(4) If the performance of the magneto is still unsatisfactory the contacts may need cleaning and adjustment, or the rocker arm may be sticking and working sluggishly. Badly worn or burned contacts should be replaced by a new Lucas contact set. Should the contact breaker be in good order check the pick-up and high tension pick-up brush. Failing this being responsible there may be an internal fault in the magneto. If this is suspected the advice of a Lucas Service Agent should be sought.

Removal of Magneto.

Remove the timing cover, and engage first gear to holil the crankshaft stationary. Unscrew the hexagon headed centre screw in the automatic timing unit. The screw will loosen and then, almost at once, tighten again. This tightening is caused by the extraction thread coming into operation, and another turn will free the timing unit from the magneto spindle, enabling it to be taken out. Take off the three nuts and washers holding the triangular flange of the magneto to the crankcase. If the cylinder is in position a waisted 7/16-in. box spanner will be needed to reach the upper nut nearest the crankcase. The standard spanner LE479 may be modified quite easily to suit.

Refitting the Magneto.

Place the automatic timing unit in position meshing the gear with the intermediate gear, and with the hexagon head screw held against the unit, and the magneto flange gasket in place, push the magneto over the studs, entering the magneto shaft in the centre of the timing unit.

Screw the hexagon headed centre screw on to the magneto shaft holding the head firmly against the mechanism, and allowing the magneto to locate itself under the influence of the screw.

Fit the three flange washers and nuts and tighten fully. See remarks in preceding section re spanner.

Re-time the magneto—-see page 49, and finally refit the timing cover.