About The Site

Description of Working.

Suspension is by coil springs (19), oil damped. The oil for damping and lubrication is carried in the fork struts.

The working is as follows : On extension of the fork, that is on recoil after a shock, the damper tubes (45) attached to the unsprung sliders move downwards away from the damper piston rods (24) which are fixed at the top to the adaptors (3) on the sprung part of the fork. The damper pistons (47) move into contact with the damper piston rod washers (48) closing the valves. The upward movement of the pistons relative to the damper tubes causes oil from the sliders (27 and 42) to be drawn through radial holes in the damper tubes to fill the spaces below the pistons.

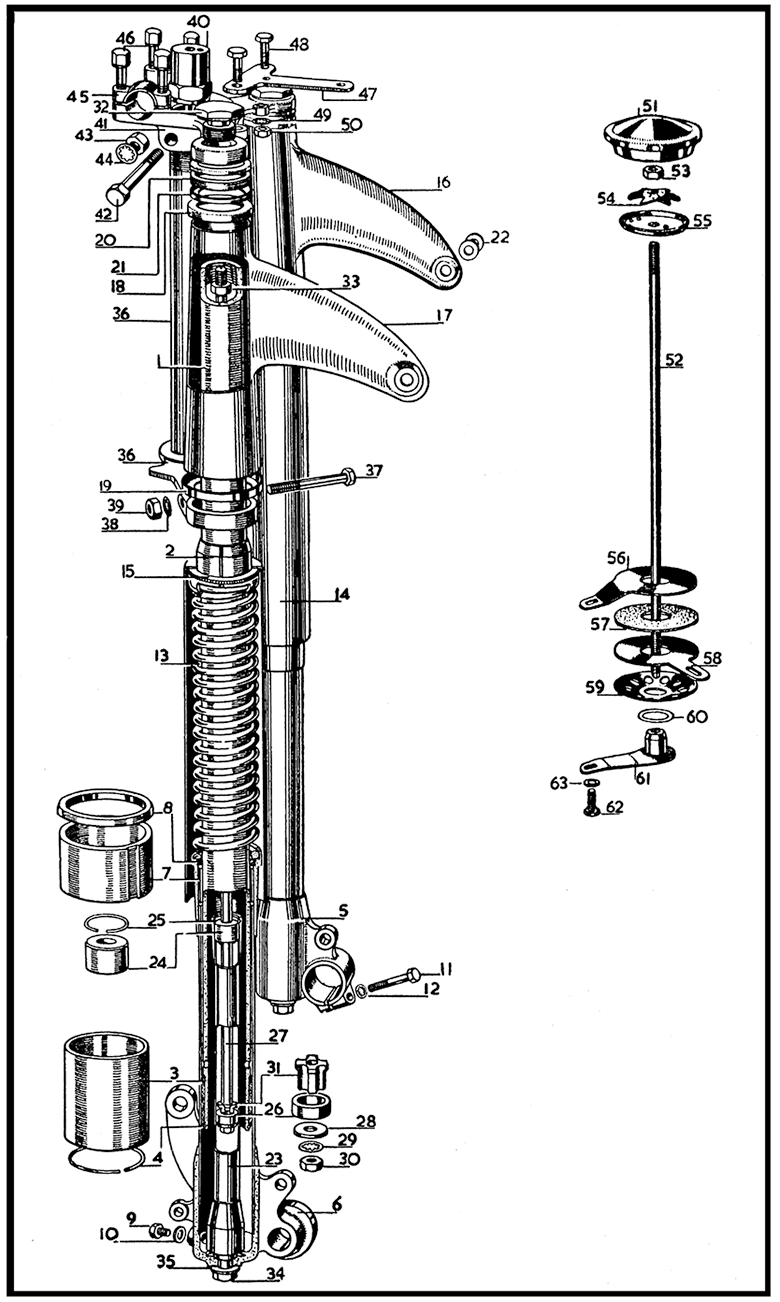

FIG. 3. THE VELOCETTE TELESCOPIC FORK WITH STEERING DAMPER

On compression of the fork the movement is reversed and the damper tubes move upwards relative to the piston rods, and the pistons lift off the piston rod washers, allowing oil to pass freely from below the pistons through the damper valves (46) into the upper parts of the damper tubes.

Again on recoil the damper tubes below the pistons are replenished, but the oil above the pistons is trapped and can get out only through restricted openings at the top ends of the damper tubes, providing the resistance necessary to give the desired degree of damping.

Oil from the upper ends of the damper tubes drains down into the sliders and is available for use again. The outer lower ends of the damper tubes are shaped to form cones, and any impact sufficient to force the sliders up almost to their limit brings the open ends of the fork tubes (12) over the cones, and a hydraulic lock is formed which prevents metallic contact and "bottoming" in severe conditions.

During the whole time the machine is running over rough surfaces the above cycle of operations is going on, and the more irregular the surface the greater is the degree of damping. It has been found that over almost smooth surfaces the fork works almost undamped and moves freely over slight inequalities in the road, thus overcoming the objection usually found with most damping systems that they prevent movement of the fork altogether under slight impact.

Maintenance.

Apart from external cleaning, the fork needs no attention. The oil supply lasts almost indefinitely and topping up is unnecessary. Should an owner wish to do so the oil may be drained out and fresh oil put in after 10,000 miles running.

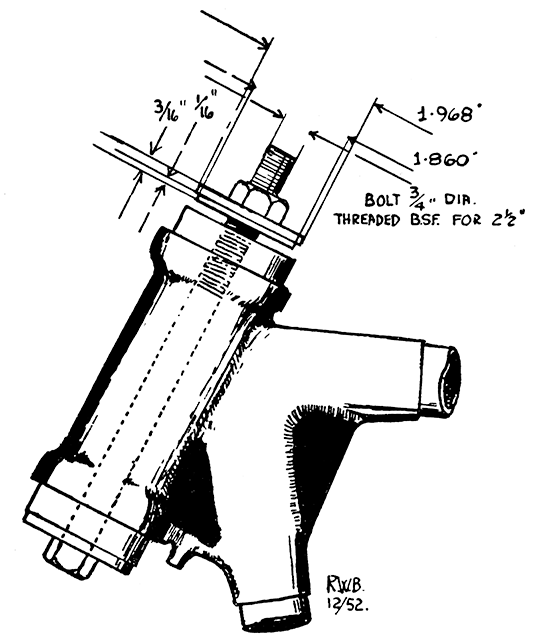

Drain plugs (28) are fitted into the bottom of the sliders at the rear. After refitting the drain plugs, unscrew the two adaptors (3) from the top of the fork tubes. They can then be lifted far enough to get oil in quite easily. pint (71 c.c.) will be needed in each side.

The Fork Spring Dust Covers. (Fig. 3.)

Occasionally a slight rattle may develop due to a loose dust cover. This must be rectified at once otherwise the rubber washers (17) between the inside of the dust covers and the split sleeves (16) will be damaged and will have to be replaced.

To eliminate rattle the split sleeve on the side needing attention has to be moved up the fork tube to " nip " the buffer. To do this first drain out all oil from both fork sliders. Slightly loosen the clamp bolt (41) on the side required. Do not slack it right off.

Bounce the front wheel sharply several times on the ground until the cover is prevented from rattling and retighten the clamp bolt. The dust covers will never be held so firmly that they cannot be turned by hand, but they must be secure and unable to rattle.

Complete draining of the fork is essential to avoid forming a hydraulic lock which otherwise will prevent the full closure of the fork springs, and the split sleeve will not move. Only partial slackening of the clamp bolt is required as if it is loosened too much the sleeve will move down again when the spring extends.

Dismantling the Fork. (Fig. 3.)

After removal from the machine—described previously—hold the steering column in a vice so that the fork is horizontal. Cover the jaws to prevent damaging the column. The procedure deals with only one strut, but it applies equally to both. Only the sliders (27 and 42) and the lamp bracket assemblies (37 and 40) are "handed" and their positions must be noted for correct reassembly.

Pull off the two buffer housings (9) and the locating cup from the top of the lamp bracket assembly. Remove the lamp bracket assembly and the cup (13) in which it is located at the bottom.

Slacken off the clamp bolt (41) fully and pull the split sleeve (16) with the main tube, spring, dust cover, and slider, etc., through the bottom cross member of the column assembly away from the column. Twist the assembly when pulling which will make it come away easier.

Remove the column and the other assembly from the vice. Pull off the spring dust cover (18) and the rubber buffer (17) from the split sleeve. Hold the top end of the main tube (12) horizontally in the vice, hold the spring, and tap the split sleeve round until it comes free of the spring. Take the tube out of the vice and remove the split sleeve from it. Hold the slider in the vice and by grasping the spring firmly, twist it out of the mounting on the slider.

Take the slider in one hand and the main tube in the other and after pushing the slider up the tube as far as it will go, draw them apart as sharply as possible to dislodge the oil seal (20) and the slider bush (21) from the top of the slider. The main tube with the fork tube bush (25) will then come away. To remove the fork tube bush first prise the the circlip (26) from its groove in the end of the tube and tap the bush carefully off the tube.

The Fork Damper Assembly is removable from the slider after removing the nut (31) and washer (30) from the end of the slider, and will tap out of place. To dismantle remove the damper bush circlip (22) from the damper tube and remove the bush by a similar process to that adopted to remove the slider bush and oil seal from the slider. The damper piston rod (24) with the piston and valve, etc., will then pull out. If the piston (46) or damper valve (47) are removed note the correct order of replacement and see that the shiny face of the piston is set facing the bottom (next to the washer (48). Also when replacing the damper bush (23) note that the end with the chamfer fits uppermost, otherwise the circlip will not go into place.

Reconditioning - a Warning. The slider assemblies will be seriously damaged if stoved at temperatures exceeding 212° Fahrenheit after re-enamelling.

Reassembling the Fork. (Fig. 3.)

Fit the assembled damper to the slider being careful to locate the damper tube spigot properly in the hole in the slider. Fit the washer and nut and tighten. See that the fork tube bush and circlip are properly fitted to the main tube, slide the upper bush (21) over the tube and towards the bottom, noting that the groove across the end face must be facing the bottom bush.

Hold the tube horizontally in the vice and after lubricating the bushes fit the slider over it, entering the damper piston rod through the tube and the bottom bush (on the tube) in the slider. Twist the slider bush (21) to bring the groove, which is cut down the outside, to the top. Hold the slider so that the wheel spindle mounting lug points downwards. Enter the slider bush into the slider and drive it firmly into place using Service Tool LET 796, which consists of a specially shaped split collar which can be fitted over the tube. Remove the tube from the vice and fit the oil seal (20) over it and slide it down to the top of the slider into which it must be fitted by using Service Tool LET 796 once more. Slide the spring down into position and by holding the slider in the vice twist the spring firmly into its mounting. Extend the slider along the tube as far as it will go.

Push the split sleeve (16) down the tube until the upper edge of its taper section is set exactly 7.187-in. (7 3/16-in.) from the top of the tube. Hold it firmly in this position and push the slider and spring towards it, engaging the spring in its mounting on the split sleeve and twisting it firmly into place. Invert the assembly until the damper piston rod protrudes from the tube and attach a piece of wire to it as described on page 12. Fit the rubber buffer (17) and dust cover (18) over the sleeve, thread the wire, and the tube through the bottom cross member, and partly tighten the clamp bolt. Note that the assembled tube, spring and slider are fitted on the correct side. The slider which carries the wheel spindle clamp is always on the left (remote from the brake drum).

When assembling the fork—prior to refitting it to the machine—always set the struts so that the fork ends of the sliders point over to the right at about 20° off the centre line. This ensures that when the wheel is fitted after the clamp bolts (41) are tightened the sliders tend to hold the springs firmly into their mountings.

Reassembly of the lamp brackets only calls for care in fitting them to their respective sides and seeing that they are located properly in their top and bottom collars and that the top buffers are fitted between the hollow (concave) sides of the buffer housings.

The wires attached to the damper piston rods enable these to be drawn up for the attachment of the adaptors (3).

Before refilling with oil verify that the dust covers do not rattle, and after fitting the wheel make certain that the fork works freely before finally tightening the spindle clamp bolt. If the dust covers are loose see page 15.

Setting the Front Mudguard Stays.

As a fork is seldom removed and dismantled unless the machine is accidentally damaged, care should be taken when fitting the front mud¬guard stays, whether new or repaired ones, that they go into place without having to be forced. Before fitting them therefore they must be set to the correct widths between the ends as follow :

Front stay 6 5/8-in. (6.625-in.);

Central stay, 6¾-in. (6.75-in.) ;

Bottom (rear) stay fitted outside the centre stay, 6½-in. (6.5-in.).

In any instance where the fork does not work freely, and this is not due to the wheel mounting, remove the stays and reset them if needed.