About The Site

Removal of Cylinder and Piston.

The removal of the cylinder head is dealt with on page 22.

Remove the cylinder barrel. This will be made easier if the crankcase bolts and studs are freed off first. Note that if compression plates are fitted between the cylinder and crankcase they must be kept aside for refitting when rebuilding the engine.

The piston is removable after taking out one circlip and driving out the gudgeon pin. A slot will be found running into the circlip groove at one side of the piston for the purpose of allowing a sharp bradawl or scriber to be inserted under the circlip to prise it out. Use a soft metal punch against the opposite end of the gudgeon pin, have an assistant support the piston against the force of the blows and drive out the gudgeon pin. Help is essential here otherwise there is a risk of bending the connecting rod and setting it out of line. The pin is a light driving fit when the piston is cold.

Inspection of Cylinder, Piston and Rings.

Examine the bore for wear or scoring. The original bore diameter is 2.677-in. Reboring is generally considered necessary if wear in excess of .008-in. has taken place or the bore is damaged or scored. Cylinders do not wear uniformly, but the maximum wear will be found to have occurred towards the top of the bore at the back. To measure the wear therefore, take an accurate reading of the diameter from front to back, just below the ridge left at the top end of the ring travel. This reading may then easily be compared with a measurement taken below the part traversed by the rings which will usually be found almost unworn.

Piston rings should be examined for uneven bearing on the cylinder, excessive gap, or side play in the grooves. Any patches of discolouration on the bearing surfaces of the rings indicate that blow-by has been taking place and renewal may be necessary. The ring gaps of course increase with wear and may increase up to .025 to .030-in. before replacement.

New piston rings are supplied by us correctly gapped and in an unworn bore the gaps are :

| Compression rings : | .0085-in. to .0115-in. |

| Oil control ring: | .0105-in. to .0135-in. |

Side clearances are :

| Compression rings : | .0005-in. to .0025-in |

| Oil control ring : | ..0025-in. to .0045-in. |

Pistons and rings are obtainable in three oversizes +.020-in. and +.040-in., and +.060-in. on diameter. Oversize piston rings cannot be fitted to a worn bore unless the bore is reground to the correct diameter of the replacement rings, in which case an oversize piston would be essential also.

Dismantling the Timing Cover and Timing Gears.

The timing cover is held to the crankcase by ten screws. Remove these and tap the cover gently at the edges with a mallet or soft hammer to free it from the joint face and pull it off. Do not insert wedges between the faces.

Remove four bolts (2; 5/16-in and 2 ; ¼-in.) holding the timing gear steady plate to the crankcase and the bottom rocker and intermediate gear spindles, also take off the nut from the end of the camwheel spindle. The second nut on the steady plate holds the cam oil jet and should be left in place. Remove the steady plate.

Undo the magneto armature nut in the centre of the timing unit. After loosening, the nut will tighten and begins to withdraw the timing unit from the armature.

Pull the cam followers off the spindle, being careful to preserve the "Belleville" thrust washer which is fitted between the inlet cam follower and the crankcase. Draw from their respective spindles the camwheel assembly and intermediate gear assembly. The crankshaft pinion and oil-pump worm cannot be drawn off the shaft until the oil pump is out of the way, but the mainshaft nut (left-hand thread) may be removed at this stage. Preserve the timing shaft (tongued) washer which is behind this nut.

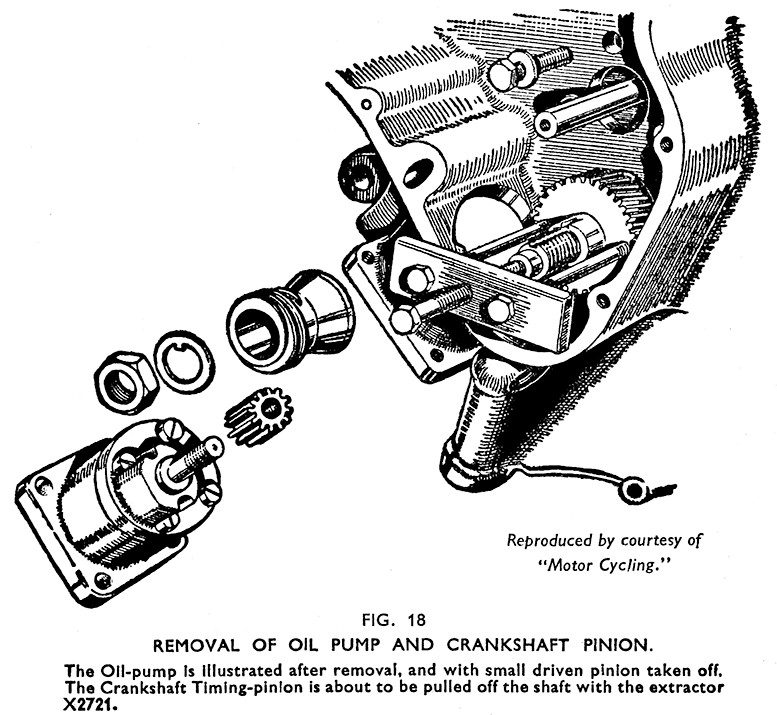

Removal of Oil Pump. (Fig. 18.)

It is important not to attempt to take out the oil pump assembly before heating the crankcase around the pump to expand the pump housing. If forced out cold the housing will be scored which may scrap the crankcase.

Take out the four oil pump fixing screws which hold the pump base plate to the crankcase . Three of the holes in the base plate and two of those in the crankcase are visible in the illustration.

Note that the screw fitted to the inner front corner is longer than the other three.

Heat the crankcase around the oil pump housing. A blow lamp may be used if care is taken not to play the flame continuously on one point and overheat the metal. As the metal is warmed up tap the pump carefully on the top from inside the timing case until it comes clear. Do not tap on the end of the pump spindle. Do not take the oil pump apart unnecessarily. It is seldom that it needs any attention, and if working freely, and if there has been no lubrication trouble it is best left alone, as a special tool is needed to rebuild it.

Dismantling the Oil Pump.

Take out the four screws securing the pump body and its cover to the base plate. Removal of the plate exposes the two return gears and the cover will pull off the pump body bringing with it the pump spindle and the feed gear cut integral with it. The two return gears and the loose feed gear are then removable from the housing, but as they are taken out mark them with indelible pencil for replacement in the same positions, as it is possible for the two loose gears to be fitted inverted. This is not recommended once the gears have been working and have bedded in to the respective matching gears on the driving spindle.

Overhauling the Oil Pump.

When inspecting the pump make sure that the fixed spindle is firm in

the body, and scrutinize the recesses in the pump body, in which the gears run, for any signs of scoring on the walls.

To work efficiently the pump gears must have the minimum clearance possible between the tops of the teeth and the body. They must also revolve freely when the pump body and cover are bolted to the base plate with as little end float as possible.

End float is removable by lapping down the appropriate end face of the pump body so that when in place the gear end faces are practically flush. Any lapping needed must be most carefully done using medium grade grinding compound and rubbing the pump face whilst held quite flat on a surface plate or sheet of plate glass.

Should new gears be fitted, carefully inspect them for any roughness or fraize around the edges and remove this very carefully indeed by polishing with a strip of superfine emery cloth (Grade 00) held on a small file. To take out the spindle from the oil pump cover remove the driving gear which meshes with the worm on the mainshaft. Hold the spindle firmly and unscrew the gear anti-clockwise. A convenient method of holding the spindle to avoid damage is to get a scrap splined return oil pump gear, file flats opposite to each other, and hold it in a vice. The splines of the spindle can then be held in the splines in the gear whilst unscrewing the driven gear.

Reassembling the Oil Pump.

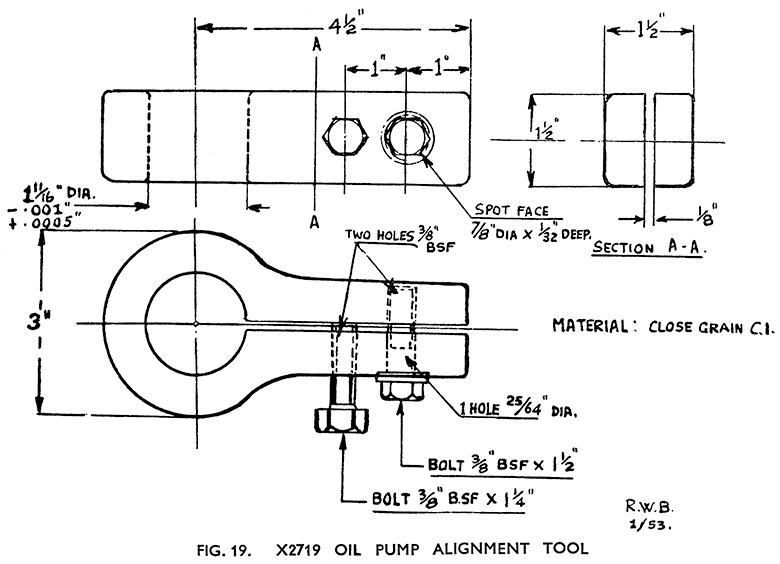

After reassembling the gears and spindle to the pump the pump cover has to be accurately lined up to the body before tightening the four oil pump screws holding the pump to the base plate. For this work Service Tool X2719 oil-pump alignment tool is required (Fig. 19).

The pump body and cover, loosely mounted to the base plate, are clamped in the tool and the four screws tightened up. Test the pump for freedom of working by turning the spindle. If tight, try slackening off the four screws. If this frees the pump gears the trouble is lack of end play and the pump must be dismantled, the offending gear or gears located, and eased off by lapping down their end faces perfectly square to the bore.

Slight roughness or "lumpiness" can be cured by running a mixture of oil and Turkey stone powder through the pump whilst the pump spindle is rotated in a lathe or drilling machine. After this treatment complete dismantling and scrupulous cleaning in petrol are essential before putting the pump together again in the alignment tool, tightening the body to the base plate and refitting to the engine.

Refitting the Oil Pump to Crankcase.

Heat up the crankcase around the oil pump housing using a blow lamp, but taking care to keep the flame moving about and not concentrated on one spot. Make certain that the crankshaft timing pinion and oil pump drive worm are fitted as they cannot be got into place after fitting the pump. Fit a new base plate gasket over the pump.

Push the pump into the housing lining up the holes in the pump base plate with the screw holes in the crankcase and meshing the driven gear with the worm. The illustration on page 39 (Fig. 18) shows how the pump is located. Tap the pump home and fit the four fixing screws. Note that the short screw fits into the inner front screw hole. This hole is just visible in the illustration in the right-hand bottom corner of the base plate.

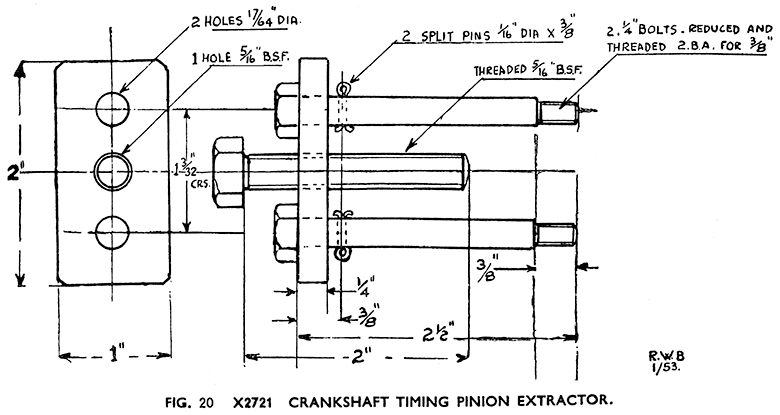

Removal of Crankshaft Timing Pinion. (Fig. 18.)

After removal of the oil pump and the left-hand thread mainshaft nut (unscrewed by turning clockwise) pull off the tongue washer behind the nut, and draw the pinion off the shaft, using Service Tool X2721 (Fig. 20).

This is attached to the pinion as shown in Fig 18 and the tightening of the centre bolt draws the pinion from the mainshaft.

Separating the Crankcase Halves.

Removal of all crankcase bolts and studs enables the case to the opened up. The roller race centre will easily come out of the bearing outer ring in the driving side crankcase, but it may be necessary to tap the timing side shaft out of the timing side ball bearing which should be left in the case.

The ballrace can be tested for play or roughness whilst in place, and it is possible to inspect the roller track in the driving side bearing outer ring. If it is suspected that the roller track on the inner ring is worn or pitted, one of the rollers may be pulled out of the cage to enable an examination to be made.

Removal of Main Bearings.

The crankcase must be heated around the bearing housings to free the ballrace and the roller race outer ring. A blow lamp may be used or the case may be heated over a gas ring, provided that care is taken not to concentrate the flame on one point. It is safer to immerse the case in boiling water and allow it to reach the temperature of the water.

When hot take up the case, protecting the hands with rag, and bring-down the open side smartly and quite square on the bench top or on a large block of wood to jarr the bearing or roller race outer ring out of place.

The end float on the flywheel assembly is controlled by the distance between the bearings and during initial assembly it is usual to fit packing shims of various thicknesses between the outer rings of the bearings and their housings in the crankcase, to take up excess end float. These shims are produced in three thicknesses, .003-in., .005-in., and .012-in. Any shims found in the housings on removal of the bearings must be retained and a note made of the side from which they were taken.

The centre ring, rollers, and cage of the driving side bearing can be re¬moved from the mainshaft by levering off the centre ring.

Refitting or Renewing Main Bearings.

The mainshafts taper gradually from the flywheels outwards, and the bearings are internally tapered to suit. The taper cannot be detected by eye, but the "large" ends of the bearing inner rings are noticeably radiussed from the end face into the bore - the "small" ends being sharp cornered. If in doubt offer the bearing up to the shaft and, with the fingers only, try to push it on to the shaft. If it is the wrong way round it will hardly go on at all with the finger pressure. All Hoffmann bearings have the maker's name and identification number on the "small" ends, so that these will be outwards and remote from the flywheels when fitted.

Fit the roller race centre to the shaft, tapping it into position up to the shoulder of the flywheel.

Heat the crankcase around the bearing housings (see above), and fit into the bearing housings any packing shims that were removed on dismantling, or new ones of the same total thickness. Fit the ball bearing to the timing side case placing it quite square into the housing and tapping it home quickly, being careful that it is the right way. round. Fit any shims needed to the driving side case and place the outer ring squarely in position, noting that the internal lip on this must be towards the bottom of the housing, otherwise the rollers will not enter.

Refitting the Flywheel Assembly.

The work on the big end, described on page 43, is assumed to have been carried out, or to have been unnecessary and the flywheel assembly ready for replacing in the crankcase. See that the intermediate gear spindle is fitted. It cannot be put in after the crankcase is assembled.

With the timing side crankcase resting on the bench upon its timing case face, place the flywheel assembly in position entering the timing side mainshaft into the timing side ballrace, and push the shaft home. See that both joint faces are scrupulously clean and place the driving side case into position entering the rollers into the ring in the crankcase.

Fit all the bolts and studs, and tighten these slowly and evenly so as to bring the faces together quite square. As the tightening proceeds keep testing the freedom of the flywheel assembly and as soon as there is any sign of stiffness due to the bearings being "nipped" by the closing of the crankcase stop tightening the bolts and nuts.

With clearance (feeler) gauges find the extent of the gap left between the crankcase face joint, checking the gap all round so as to be quite certain that the bolts and nuts have been tightened evenly.

It is possible that the halves of the crankcase will pull right up together and still leave the flywheel assembly quite free to turn in the bearings. If this is so tap the assembly first to one side, and then to the other to find the extent of the end float present. If there is end float this must be checked and a note made of the amount to be taken out, and the extent of shimming required.

The flywheel assembly must be assembled into the crankcase finally so that with all studs and bolts tightened fully, there is perfect freedom of rotation with no noticeable side play, or at least as little as possible, so as to give about .001-in. freedom when the crankcase gets hot. It is, how¬ever essential to avoid any trace of stiffness, and consequent artificial side load on the bearings.

Should alteration to the shimming be required the crankcase must be separated, the ball bearing, and roller bearing outer ring removed, and shims taken out or fitted according to whether additional freedom is needed, or whether play is be removed.

To give freedom remove a packing shim or shims whose total thickness is equal to, but in no circumstances less than the gap which was measured between the crankcase halves at the point where tightening began to "nip" the bearings, being careful to arrange as far as is possible for an approximately equal thickness to be left at each side. For instance should .012-in. shimming be needed, it would be undesirable to fit one .012-in. shim, and two each of .003-in. should be fitted at each side. Should .008-in. shimming be needed there would be no objection to .003-in. one side and .005-in. the other, as the difference is not so great.

If there is too much play fit shims equivalent in thickness to the amount of play to be taken up (or slightly less). In this case also if two or more shims have to be used try to make up about the same thickness at each side.

If no alteration is needed just separate the faces far enough for them to be coated lightly with jointing compound (Gasket Goo—made by The Wilcott Parent Co., Fishponds, Bristol, is recommended) after which the bolts and nuts may be finally tightened.

Overhauling the Flywheel Assembly and Big-end.

The shanks of the crankpin taper outwards towards the threaded ends and it is secured by nuts to the flywheels. To separate the flywheels for the purpose of inspecting the big-end bearing one nut must be removed and the crankpin pressed out of one of the flywheels. A special box spanner —Service Tool No. X2720, is required for the removal and refitting

of the crankpin nuts which are Whitworth (1.3-in. across the flats).

The outside diameter of the spanner around the hexagon must not exceed 1¾-in.

The nuts are invariably very tight, good leverage is essential to move them, and the flywheel has to be held really firmly whilst loosening or tightening up. After taking off the nut, support the flywheel to be removed and drive out the pin using a brass or aluminium drift to protect the threaded end.

The connecting rod is then removable, leaving the cage and rollers on the pin. Mark the connecting rod so that it may be replaced the same way round. Inspect the bearing outer ring in the connecting rod for signs of pitting or uneven wear, and if necessary to renew, press out the worn ring and press in a new one, locating it centrally in the eye of the rod.

Whilst dealing with the big end check the fit of the gudgeon pin in the small end bush so that this bush may be replaced at the same time should it be worn. See also page 45.

Pull the cage and rollers off the crankpin and inspect the roller track for wear and possible pitting, or breaking up of the hardened surface.

Some wear will almost certainly be noticed at the sides of the roller track where the roller cage bears on the crankpin sleeve. Provided that this is not excessive so as to leave the roller track unsupported it may be disregarded.

Oversize rollers may be employed to take up slight play, but must only be fitted if the tracks are even and free from pitting. These rollers are obtainable .0002-in. and .0004-in. oversize on diameter. The standard diameter is .1875-in. (3/16-in.). The standard sleeve diameter is 1.374-in.

The final assembly of the big end should leave the connecting rod quite free and a hardly perceptible amount of vertical play is permissible without oil in the bearing. There will be about .008-in. side play. Slight stiffness may be overcome by carefully lapping the ring in position in the connecting rod, or lightly polishing the crankpin sleeve.

To fit a new crankpin the nut at the other end must be taken off and the pin driven out of the flywheel.

Before fitting a new pin make certain that the oil-passage through the timing side mainshaft and flywheel is quite clear, and also that there is no restriction in the oil hole in the crankpin sleeve.

Place the pin in position lightly in the timing side flywheel setting the oil outlet hole in the roller track to point towards the centre of the flywheel, i.e., vertically downwards at top dead centre.

Tighten the nut enough to draw the shoulder of the crankpin assembly (the side of the sleeve) just up to the flywheel, but no more. With a force feed oil can squirt oil into the hollow timing side shaft and verify that it comes through and out of the oil hole in the sleeve.

Fit the roller cage with the rollers which if desired may be stuck into place with a little clean soft grease. Fit the connecting rod over the rollers the same way round as originally fitted. Place the driving side flywheel in position roughly lining up the rim with the timing side and pull down the nut to bring the flywheel up to the side of the crankpin sleeve.

Lining up the Flywheel Assembly.

A pair of V blocks of suitable size, a surface plate, and Dial indicator are required to carry out this work. The assembly has to be supported in its bearings - temporarily fitted to the mainshafts - in V-blocks on a surface plate. The V-blocks must be large enough to support the main shafts (at least 5-in. centre height from the surface plate).

Line up the flywheel rims using a straight-edge across them, testing at several different points round the circumference. A heavy copper headed hammer or a lead lump is needed to jar the flywheels on the pin to alter the alignment.

Mount the assembly in the V-blocks, rotate, and check the shafts for accuracy with the Dial indicator. Any malalignment is corrected by taking up the assembly and striking whichever wheel needs correction at the point indicated by the spinning test. The setting must bring the shafts running to within .001-in. of exact truth.

Tighten the nuts and check again. Finally, line up if needed by using the lead lump.

Replacement of Small End Bush.

Any vertical play on the gudgeon pin in the small end bush calls for replacement of the gudgeon pin or bush, or both. If the pin is worn it is worth trying a new pin in the original bush before deciding to renew the bush. Gudgeon pins are listed .001-in. oversize so that even if the bush is worn it might be satisfactory with an oversize pin.

Whilst it is possible to draw out a small end bush and draw a new one into the rod with a suitable bolt and collars, etc., we do not recommend attempting to renew it unless the engine is dismantled and the connecting rod removed.

All connecting rods are checked and trued in production after the bushes are fitted and finished to size, ensuring perfect alignment between the small end and big end bearings, and this cannot be guaranteed when other methods of fitting are employed. Further, as the replacement bush has to be filed in position to match up with the oil hole in the connecting rod there is a serious risk of filings getting into the crankcase. Connecting rods sent to us for rebushing will be lined up, before return, on a special fixture.

Refitting the Piston and Cylinder.

If the magneto has been removed refit it before fitting the cylinder. It is essential after reassembling the flywheels and crankcase, particularly if a new small end bush has been fitted, to check that the bore of the small end is in line with and parallel to the big end. To test; obtain an accurately ground mandrel of 5/8-in. diameter to fit closely and without play in the small end bush. Set the flywheels so that the lower edges of the small end bush are nearly flush with the cylinder face on the crankcase. Push the mandrel through the bush and check that it lies flat on the face at both sides of the small end. Should it touch at one side, but not on the other, the con¬necting rod must be reset.

The small end eye must also lie centrally in the mouth of the crankcase to avoid side thrust on the piston and this point should be checked, making due allowance for side play on the big end.

Fit the piston in place and push the gudgeon pin through the bush, finally driving it home up to the circlip, which will have been fitted to the piston. It is a help when fitting if the pin is first pushed into one boss so that it just protrudes inside the piston. The protruding end is then easily entered into the small end bush. Get help to support the piston from the opposite side when tapping the pin home. Note that the split in the piston skirt must be at the front. Finally fit the second circlip verifying that it fits properly down in its groove, and see that the ends do not touch.

New circlips are occasionally found to need a small amount removing from one end to prevent the ends touching, which would prevent proper seating in the circlip groove.

Smear the cylinder bore with clean oil, fit a new gasket over the cylinder base, sticking it in place with a little grease, and if any compression plates were fitted originally fit these in place on the crankcase. Set the ring gaps 120° apart.

Support the piston and lower the cylinder over it compressing the rings one at a time to enter them in the bore. Lower the cylinder into place and push it firmly into the crankcase.

The reassembly of the cylinder head and overhead valve gear is dealt with from page 25.

The Timing Gears.

The timing gear bushes in the camwheel and intermediate gear wheel assemblies seldom need replacement, but if renewed must be bored to suit the spindles and not reamed. Boring is essential to ensure the bearing being concentric with the gear teeth. The camwheel bush must be bored to .001-in. above the spindle diameter, and the intermediate gear bush to .0015-in. larger than its spindle. End float on the gears must not exceed .0015-in.

End float must be checked after fitting the steady plate with this bolted firmly in place.

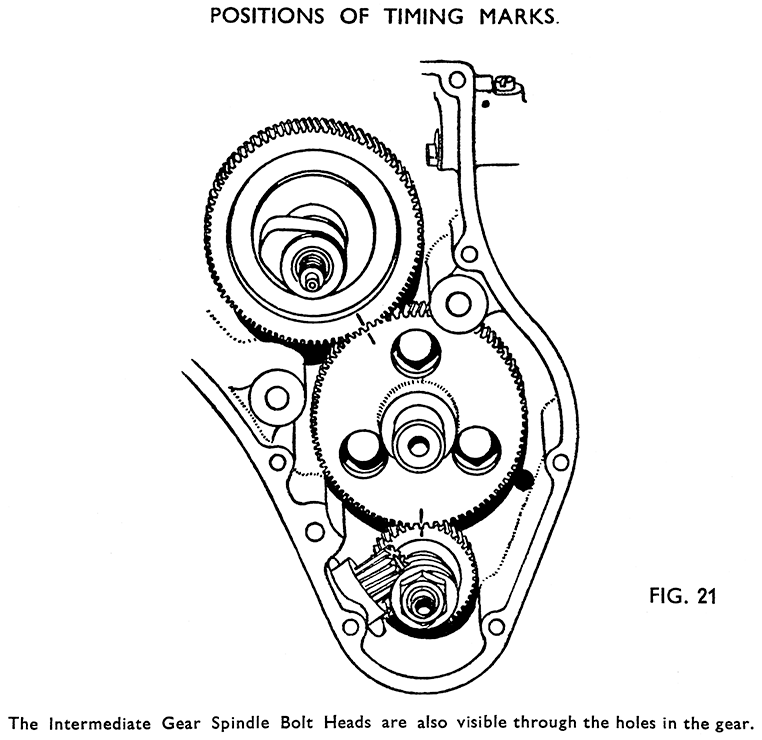

The gears are marked for refitting (Fig. 21). To fit, turn the crankshaft to bring the mark on the crankshaft pinion to the top. Fit the camwheel to its spindle setting the timing mark as illustrated and the cams pointing rearwards. Slide the intermediate gear into place and mesh its teeth with the camwheel and crankshaft pinion so that the marks register. There are two marks on the intermediate gear, but as they are not diametrically opposite the gear can only be fitted in one way to register the marks properly, i.e., with the longer section between the marks facing the front.

Note specially that owing to the intermediate gear having one more tooth than the camwheel it changes its position in relation to the other gears and lags behind the camwheel one tooth in every two turns of the crankshaft.

The result is that after resetting the timing gears with all marks coinciding, and then turning the crankshaft two complete turns, the marks on the intermediate gear will be out of register with the crankshaft, and cam gears which will be back in their original positions.

This sometimes leads to the assumption that an engine is incorrectly timed as obviously the chance of the engine stopping so that the marks are in register or even nearly so is exceedingly remote. The marks will all co¬incide only once every 93 turns of the crankshaft. This feature of the design avoids loading the same teeth at each revolution of the camshaft and evens out any wear which takes place.

The Adjustable Intermediate Gear Spindle.

Mainly for purposes of original assembly the spindle carrying the intermediate gear is arranged to be adjustable, so that the backlash between the teeth of the gears may be varied. The adjustment normally does not need any alteration, and the spindle is set when new to give freedom in the gears at all positions with minimum clearances between the teeth.

The flange of the spindle is secured to the inner wall of the crankcase by three ¼ -in. B.S.F. bolts which pass through clearance holes in the crankcase thus permitting a certain degree of movement. The flange which is machined with a flat is located by this flat portion fitting against a corresponding flat machined on the crankcase, thus allowing the spindle lateral movement only.

The heads of the spindle holding bolts are accessible through the three holes in the intermediate gear and are shown in Fig. 21, page 46.

Should excess backlash develop between the gears the adjustment may be made by removing the steady plate, slightly slacking off the three bolts and pushing the intermediate closer into mesh towards the rear (towards the left of the illustration).

It is important not to set the gear too close as this will cause gear whine.

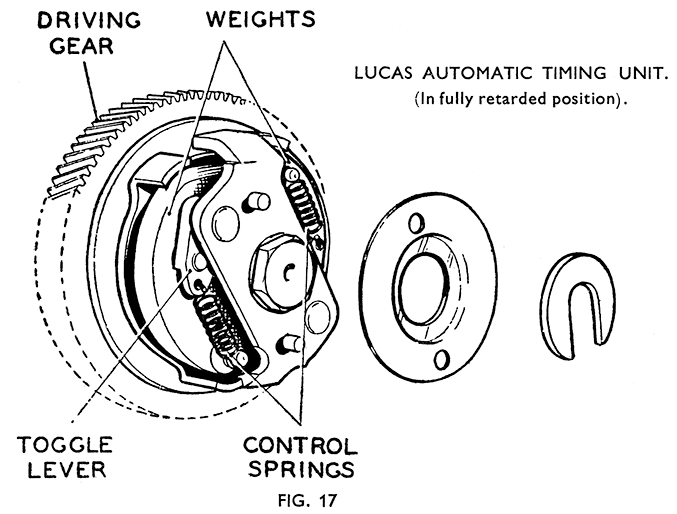

Retiming the Ignition.

Refit the automatic timing unit loosely to the magneto armature. Attach a timing disc to the driving side mainshaft and fix a pointer made of stiff wire to some convenient fixed point, i.e., one of the engine or crankcase bolts. Bring the piston to top dead centre with both valves closed and bend the pointer to indicate zero on the timing disc. Turn the crankshaft backwards 38° as indicated by the pointer. With finger and thumb turn the front plate of the timing unit backwards to its limit, to advance it fully. The plate referred to carries the toggle levers and is shown in Fig. 17, page 38.

The illustration shows the unit fully retarded. Holding the timing unit fully advanced set the contact breaker points just opening (apart by .0015-in.) The contact breaker gap must of course have been adjusted previously to the setting recommended by the magneto makers. Tighten the centre bolt to fix the timing unit to the taper on the armature. Check the timing before fitting the timing cover as follows:

Turn the crankshaft backwards and see that the contact points close. Open the points with the fingers and place between them a piece of cigarette paper, allowing the points to close on it. Obtain assistance to hold the timing unit fully advanced or insert a small block between the projections of the front plate and the back plate on the gear to wedge them apart. Very slowly move the crankshaft forward maintaining a light pull on the cigarette paper meanwhile. As soon as the paper will withdraw from between the points stop moving the crankshaft and check the position of the timing disc. The reading must be 38°.

Remove the wedge from the timing unit, if one was used, and check the tightness of the timing unit bolt.

Refitting the Timing Gear Cover.

It is advisable always to use a new gasket which may be stuck to the cover with Gasket Goo before fitting. Check that the crankshaft oil feed jet is clear and entered in the bore in the timing side mainshaft. Also engage the holes in the cover over the projecting tip of the cam-wheel spindle and cam oil jet. Tighten the cover screws firmly and evenly. The rocker oil pipe should be left disconnected at the bottom end for the time being so that the oil feed may be checked before finally connecting it and tightening the union (see page 18).