About The Site

The mileage that an engine will run efficiently without being decarbonised depends to a great extent upon driving conditions. A new engine is the better for receiving this attention after the first 2,000 to 3,000 miles have been covered. Afterwards it will probably be found to run perfectly satisfactorily for very much greater distances without similar attention. Whilst it is impossible to lay down any hard and fast rule it may be said that generally the average private owner does the work too often rather than too seldom.

If the engine is running well, and there is no noticeable loss of power, or other evidence such as a tendency to "pink" excessively it is best not to disturb it.

During the operation do not remove the cylinder barrel, unless there is good reason to do so. Removal means disturbing the piston rings, which can never be replaced in exactly the positions in which they have settled and bedded in to the cylinder and piston, and their frequent removal and reassembly may cause an increase in oil consumption.

Removal of Fuel Tank.

Turn off the fuel. Remove the pipe; holding the taps whilst undoing the unions to prevent it twisting. Remove the carburetter. Take off the bracing strap from underneath the front of the tank. Slacken the rear holding bolt and take out both the front ones. Lift off the tank.

Removal of Rocker Box Assembly.

Remove the sparking plug. Take off the rocker oil feed pipe assembly by disconnecting it from the rocker box and timing cover. Detach the rocker cover at the right hand side, and remove the two nuts and washers from the top push rod cover flange stud. Turn the crankshaft by means of the kickstart and observe the movement of the rockers. Turn until the inlet rocker and push rod are seen to rise and then fall. The piston will now be rising on the compression stroke. Note its position through the sparking plug hole and stop turning as it reaches the top. Both valves will now be closed. This is essential before the rocker box bolts are loosened.

Slacken off all nine rocker box bolts in sequence and each a little at a time until quite free. Do not slack off one or two fully, leaving the rest tight. When all are clear of the threads raise the rocker box assembly until the flange studs are pulled out clear of the holes in the cylinder head.

Work from the right hand side of the machine and hold the rocker box assembly clear of the head. Swivel it round with the push rods as centre, in a clockwise direction towards the front until it is across the machine at right angles to its original position. Lift it up further to clear the push rods and remove it.

Removal of Cylinder Head Assembly.

Lift out the push rods, being careful not to drop out and lose the loose cups, and mark them so that they are not interchanged when reassembling. Wet indelible pencil will do.

Unscrew and remove the hollow bolts securing the rocker box oil drain pipe assembly to the head and push rod cover. Remove the gaskets and take away the pipe. Telescope the upper push rod cover into the lower section and take away the two top flange gaskets and the guide plate which is between them.

Slacken off the cylinder head nuts each a little at a time in sequence until clear of the head, and then screw them right off. If any of the studs screw out with them they can be separated later and before reassembling. Unscrew any studs left in place by applying a screwdriver to their to ends.

Tilt the cylinder head assembly off the cylinder barrel; preserving the joint gasket. It is best to leave the cylinder in place so do not disturb it.

Decarbonising.

Before removing the valves scrape the combustion head clear of carbon using a brass or aluminium scraper to avoid scratching the surface. This will prevent the valve seatings being marked. It will be possible also to clean most of the carbon from the exhaust port, but final cleaning of the port and head will be necessary after removing the valves. The port can be cleaned and polished with emery cloth. Never use emery cloth or other abrasive to clean the piston crown, but scrape off the carbon with the brass or aluminium scraper. After cleaning thoroughly, lower the piston a little in the cylinder and wipe all traces of carbon dust off the cylinder wall. Bring the piston back to the top after wiping clean.

Removal of Valves and Springs.

The Service Tool KA.163 /2 will be required to compress the valve springs. Fit this over the side of the cylinder head across the top face locating the forked end on the valve spring collar and the screw in the centre of the valve head. Tighten the screw until the split cotter is exposed and pick out the two halves. Release the compresser and take it off. Lift off the valve collar, spring collars and the valve springs. Push the valve out of the guide. Both valves are dealt with in the same manner, but the valves and split cotters are not interchangeable. Although interchangeable the springs, collars, and washers should not be interchanged after being in use and should be set aside in separate boxes marked for identification when reassembling.

Refacing and Grinding in Valves.

To avoid needless wearing of the seatings in the head by lengthy grinding-in it is recommended that the valves be polished and refaced on a valve refacing machine. The seat angle is 45°.

Remove any hard scale by using a piece of Carborundum; polishing up the surface afterwards. Do not in any circumstances polish the bearing surfaces of the stems.

To hold the valves for grinding-in, use special tools. Using fine grade compound; grind in each valve with a semi-rotary motion. Lift the valve frequently from the seating and bring it down in another position to distribute the grinding compound evenly and to prevent forming concentric rings and ridges on the seats. A light coil spring threaded over the valve stem between the head and the guide will help by raising the valve off the seat when pressure is removed from the holding tool. Aim at an even grey matt surface on the seating - not a polish.

Refacing the Cylinder Head Valve Seats.

This will only be needed alter very long service. Ordinary valve seating cutters will not be satisfactory and the seatings will need attention from a standard 45° valve refacing stone.

Refitting the Valves and Springs.

See that all traces of grinding compound and carbon dust, etc., are cleaned from the combustion head, seatings, and valve ports. Preferably blow all parts clean with a compressed-air jet after washing down the head. Be particularly careful to clean the valve guides thoroughly. A little clean rag rolled into a “pencil” and pushed or drawn through the guides is recommended.

Assemble the hairpin valve springs into the bottom collar and fit the collar and springs over the appropriate valve guide. The closed ends of the springs overlap each other.

Smear a little clean oil or graphite grease over the valve and insert the stem into the guide. Place the valve spring collar and inner rotating collar over the end of the valve stem.

Compress the springs with service tool KA.163 /2 until there is room to allow the cotter to be fitted. Smear a little grease inside the halves of the cotter and fit them into place, small ends facing the valve guide, and the lips engaged in the groove on the valve stem. Press them together and release the compresser until the valve collar holds them firmly in place. Remove the compresser and fit the other valve and springs in the same manner.

Refitting Cylinder Head Assembly.

Clean the piston crown, and the top of the cylinder barrel. See that no carbon dust is left in the cylinder bore or in the sparking plug thread. If the joint gasket is in good order refit it to the cylinder. If deteriorated fit a new one. Clean the cylinder head joint face carefully, and screw in the sparking plug. Wipe off any particles of dust, etc., dislodged by the sparking plug. Centralise the gasket and fit the head assembly into position lining it up so that the stud holes register with those in the cylinder barrel.

Thread the four long cylinder studs down through the cylinder head and barrel and screw them into the cylinder crankcase studs; using a screwdriver in the screwdriver slots at the top ends of the studs. Fit the stud washers and the special cylinder head nuts. Note that these are special nuts and ordinary nuts are unsuitable as replacements.

Tighten down carefully, a little at a time in sequence. That is : do not tighten one nut fully before the others, but work on each in turn working round until all are tight. Do not force the nuts. A good gas tight joint is obtainable without excessive tightening. The tension increases as the engine parts get hot so that over-tightening initially may cause damage later.

Refitting Rocker Box Assembly.

Fit the push rod guide plate between the two gaskets on the flange of the top push rod cover. Locate the flange and gaskets, etc., approximately with the stud holes. Fit the push rods, guiding them down through the guide plate and engage the bottom ball ends in the sockets formed in the bottom rockers.

During dismantling, the push rods should have been marked to prevent interchanging them. The inlet push rod is the one nearer the cylinder.

Carefully wipe clean the joint face on the cylinder head and the corresponding face on the rocker box. Fit a new gasket; sticking this to the rocker box face with a light smear of grease, or Gasket Goo jointing compound. (Makers: The Wilcot Parent Co., Fishponds, Bristol).

Set the piston at the top of the compression stroke. If the engine was turned whilst dismantled find this position by rotating the crankshaft forward slowly whilst the finger is rested on the inlet push rod. Turn, and note the inlet push rod rise and then fall. As it falls the piston will be rising on the compression stroke. Stop turning when the piston reaches the top. See that the two loose ends are fitted into the tops of the push rods, and refit the rocker box. This is done by holding it at right angles to its fitted position with the rocker cover opening facing the rear. Lift it into place so that the round opening for the push rods is located centrally over the push rod ends. Pivot the rocker box assembly about this point anti-clockwise into its normal position and lower it on to the head, engaging the tips of the adjustable tappets in the push rod cups meanwhile, and entering the flange studs through the holes in the cylinder head and push rod cover flange.

Fit the rocker box bolts and tighten down evenly, a little at a time in sequence. Do not tighten one bolt fully before the others, but work on each in turn until all are tight. Fit and tighten the top push rod flange stud nuts. Attach the rocker oil drainpipe to the cylinder head and push rod cover and tighten the hollow bolts, being careful not to shear them off.

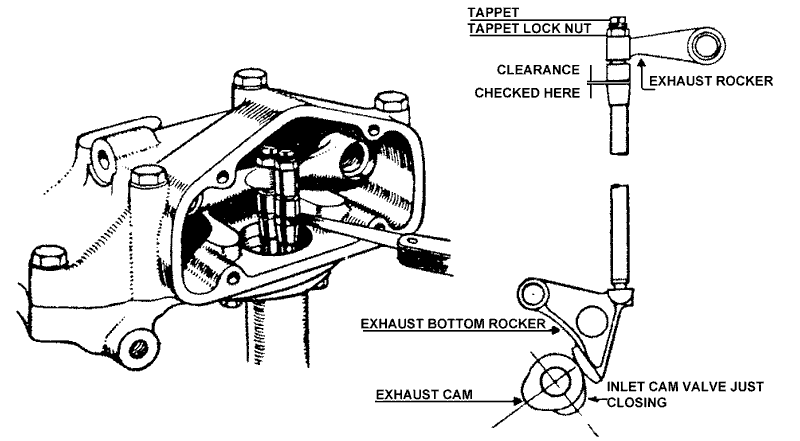

Re-adjustment of Tappet Clearances. (Fig. 8).

The running clearances must be set when the engine is cold, and must be checked and set with the bearing face of the bottom rocker resting on the base of the carn. See page 105 for Thruxton settings.

The cams are ground with quietening ramps so that the essential clearance allowed is taken up and restored gradually and there is consequently only a very limited part of each cam at which the full clearance can be checked or set correctly. The crankshaft therefore has to be turned to bring each cam into the right position before the clearance on the corresponding valve tappet is checked or set.

To obtain the two positions necessary rotate the crankshaft and observe the movement of the rockers through the opening in the rocker box. Note the inlet rocker—the one nearer the cylinder—rise, and as it begins to fall—as the valve is closing—turn very slowly until the rocker and push rod just reach the lowest point; then stop. This position; that is with the inlet valve on the point of closing brings the correct part of the base of the exhaust cam below the exhaust bottom rocker. Set the exhaust tappet clearance when the cam is in this position.

Before attending to the inlet tappet turn the crankshaft forward for about two thirds of a revolution (240°) until the exhaust valve rocker is seen to be on the point of rising. This will bring the base of the inlet cam below the inlet bottom rocker which is the only position at which the inlet valve clearance can be set correctly.

The adjustable tappets are accessible for checking and adjustment through the opening in the rocker box, and the feeler gauge is used by inserting it between the top of the push rod end (fixed) and the loose push rod cup above.

Slacken the locknut above the rocker and turn the tappet by applying the small tappet adjusting spanner to the square end. Turn clockwise to decrease clearance. A full turn will alter the clearance about .038-in. When correctly set tighten the locknut. Always re-check after locking, in case the tappet has been moved a little in the process.

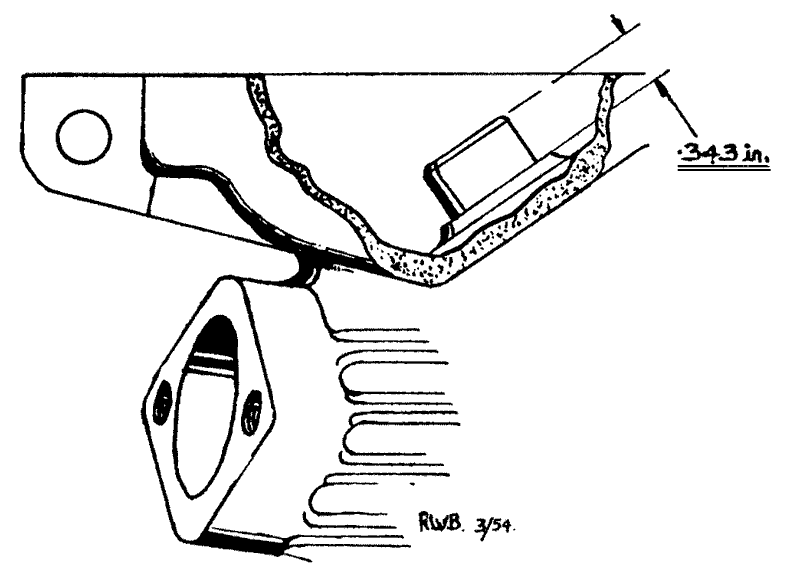

Renewal of Valve Guides. (Fig. 9.)

The valve guides are bored to allow diametrical clearances from the valve stems of .00125-in. to .0025-in. inlet, and .00125-in to .0035-in exhaust. The cylinder head is heated during manufacture when the guides are fitted. Do, not attempt to press out a valve guide unless the metal around it is heated. The temperature should not exceed about 100 centigrade (boiling point of water). Immersion in boiling water is a suitable method of heating. Alternatively the metal surrounding the guide can be heated with a blowlamp provided that the flame is not concentrated and allowed to play too long on one spot.

The head must also be heated before fitting new guides which are pressed in leaving .343-in. protruding from the machined face around the valve guide hole. True up the seats concentric with the guide bores after fitting, and grind in the valves.