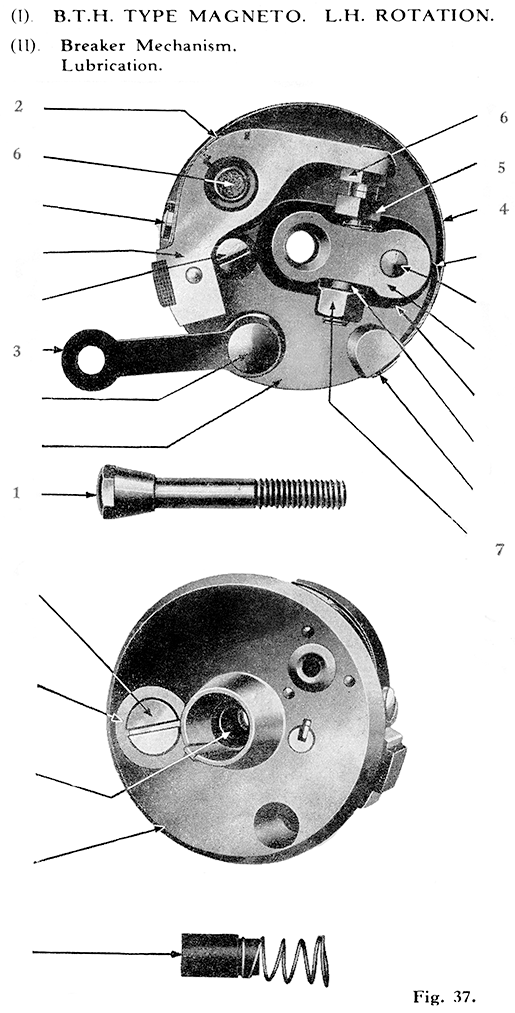

The cam is lubricated by a felt wick in the bottom of the cam ring, which should be given one or two drops of light machine oil. The cam track should also be smeared with oil, but take care to wipe off all surplus oil, leaving only a light oil film on the cam track.

The contact lever bearing is more easily lubricated when the contact breaker is removed for cleaning as described below.

The contact breaker may be removed for cleaning by unscrewing the central hexagon-headed screw (1), and withdrawing the breaker. The contact lever (2) may then be lifted from its bearing bush by first raising and then moving to one side the check spring (3) which is located in the end of the bearing bush.

Care should be taken not to distort in any way the contact lever control spring (4). The points (5) may be cleaned with a very fine emery cloth, but under no circumstances should they be filed. Wipe away any dirt or metal dust with a petrol moistened cloth.

Before replacing the contact lever smear the bearing bush lightly with thin lubricating oil, wiping off any surplus. Also apply one drop to the wick (6) in the bearing bush.

IT IS OF THE UTMOST IMPORTANCE THAT THE POINTS BE KEPT ABSOLUTELY FREE FROM OIL.

To check the contact setting turn the engine until the contacts are fully opened, and insert the 0.012-in. feeler gauge provided, between the contact; the gauge should be a sliding fit. If there is any appreciable variation from the gauge, slacken the lock nut and turn the contact screw by its hexagon head, until the gap is set to the gauge. Finally, tighten the lock nut.

(III). H.T. Cable.

Should be 7 m /m in diameter. Other sizes such as 5 m /m and 9 m /m will not fit in the H.T. Brush Holder. The cable must be replaced if the rubber insulation has perished or cracked.

(IV). Pick-up.

Periodically remove the pick-up or brush holder, and wipe it with a cloth moistened with petrol, also see that the carbon brush moves freely in its holder. Before replacing the brush holder, insert the corner of a clean cloth in the aperture in the housing so that it bears against the slip ring track and the flanges, at the same time turning the engine slowly.

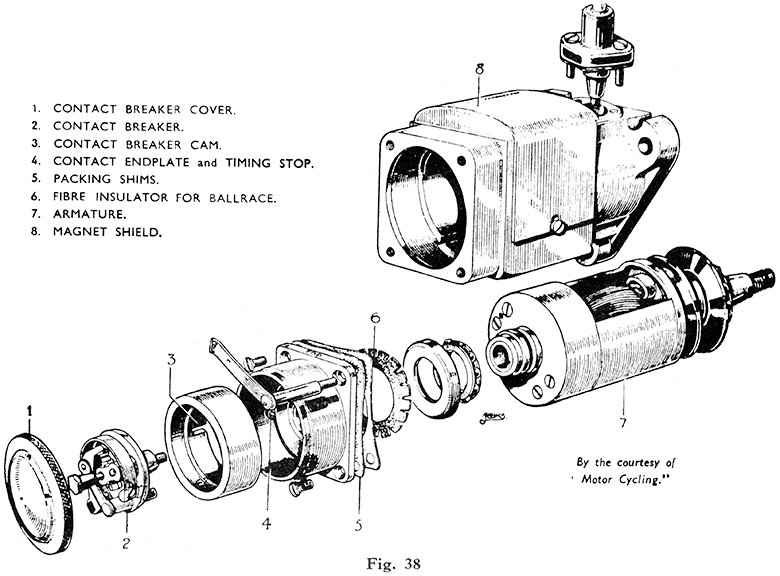

(IX). Dismantling.

Total dismantling of the magneto should be rarely necessary, but instructions are given below in case this should be required.

(1). First remove contact breaker cover and contact breaker.

(2). The collector brush holder or pick-up should next be removed before any attempt is made to withdraw the armature from the housing.

(3). The contact end plate may now be removed by unscrewing the fixing screws and the contact breaker cover spring pillar.

(4). The armature may then be withdrawn from the housing.

NOTE.—If the armature is actually withdrawn from the housing it will be necessary to re-magnetise the magnet after replacing the armature; unless a soft iron'U' shaped and good fitting keeper is placed over the magnet poles before the armature is withdrawn.

(X). Test and Repair.

If the armature has been removed it should be examined for actual structural faults, such as bent or damaged shaft, cracked or broken slip ring. Special equipment is required to check the winding and condenser and whilst a new condenser can be fitted, in the event of faults of this nature it is desirable to replace with a complete service armature.

Before re-assembling the magneto, carefully examine the bearings, which should be replaced if not in good condition. Special Extractors are required to remove the inner and outer races, and no attempt should be made to remove them by other means. If these extractors are not available, the complete magneto should be returned to the Depot for re-conditioning and a replacement fitted to the machine. When fitting new bearings the following points must be carefully watched :—

(a) The inner race must be square with the shaft, and pressed fully home.

(b) When fitting the inner race at the slip ring end, make sure the washers between the inner race and the slip rings are fitted con-centrically, so that the flat washer does not ride on the spindle shoulder.

(c) The outer races are insulated from the housing and contact end

plate, with serrated fibre washers. It is important that this fibre washer is centrally located before being pressed home.

The bearings should be packed with a suitable High-Melting Point Grease before re-assembly.

(XI). Re-Assembling.

When re-assembling, the armature should be set up with an end play of 0.002-in. This end play is adjusted by means of shims which are fitted between the magneto body and the contact breaker endplate.

When re-fitting the contact breaker great care should be taken to ensure that the key on the contact breaker base engages with the slot in the armature endplate.