It is usually advisable to decarbonise a new engine after covering the first 2,000 to 3,000 miles. Subsequently long mileages can be run without doing the work again. No set figures can be given, but it is a safe rule to leave well alone and not to disturb an engine unnecessarily and unless there are signs, such as excessive pinking, loss of power, or overheating to show that attention is needed.

Our experience is that owners tend rather to do the job too often than too seldom. The fuel tank must be removed to do the necessary dismantling.

Removal of Fuel Tank.

Turn off both taps, disconnect the pipe from them, taking care to hold the taps with a second spanner when loosening the pipe union nuts in case the taps turn and the pipe twists.

Take off the bracing strap from the threaded pummels underneath the tank at the front. Remove the tank fixing bolts at the front, slacken the rear one and lift off the tank.

Dismantling the Rocker Box and Cylinder Head.

Take off the connection to the air filter. See that air and throttle controls are shut and unscrew the mixing chamber lock ring. Pull out the air and throttle valves and tie them up out of the way to the top tube of the frame.

Detach the cylinder head steady from the cylinder head and the frame lug, undo and take off the carburetter stud nuts and washers and remove the carburetter with the fuel pipe, and the carburetter gasket.

Loosen the clips securing the exhaust pipe to the cylinder head and into the silencer. Take off the nut securing the exhaust pipe clip to the front engine plate and also detach the silencer. Take away the silencer and the exhaust pipe.

Unscrew and remove the hollow bolt securing the rocker oil pipe to the rocker cover and unscrew the union nut at the bottom from the union on the timing cover. Take off the oil pipe.

Remove the sparking plug. When doing so be very careful not to damage the threads in the head. Should any resistance to removal be felt drip a little clean paraffin or penetrating oil round the sparking plug under the washer and allow this time to percolate along the thread.

Before replacing, the threads may be coated with graphite paste or " Oil Dag " to prevent binding.

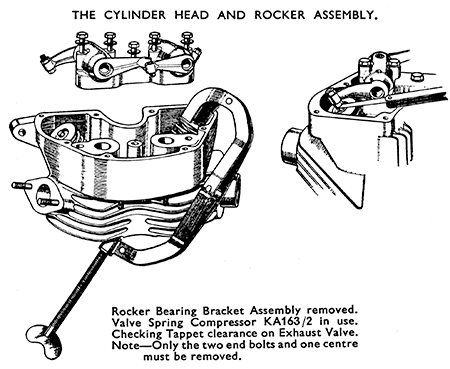

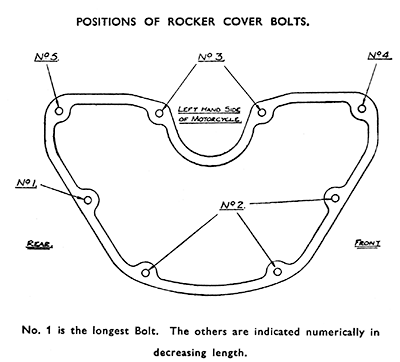

Take out all the rocker cover bolts, remove the cover. There are eight bolts in all and they are of five different lengths so that it saves time afterwards if their relative positions are marked. (See illustration page 41.) Turn the crankshaft with the kick starter until both valves are closed. Take out the three bolts holding the rocker bearing bracket assembly to the head. There are five bolts in all in the bracket, but only the centre one and the two at the extreme ends should be removed. The remaining two hold the bearing caps to the bracket. Leave these in place.

Take away the bearing bracket and the rockers, and take off the gasket between the bracket and the platform in the head.

Lift out the push rods, marking them as removed for refitting in the same places. The inlet push rod is nearer the cylinder. Indelible pencil, used wet, is suitable for marking.

Unscrew and remove the four cylinder head nuts. Two

are accessible on the left-hand side of the head outside the rocker chamber and the other two are down inside the two holes which are exposed when the rocker bearing bracket is taken off.

Take off the nuts holding the pushrod cover flange to the head, and slide the upper section of the cover down off the studs and into the lower section.

Take away the push rod guide plate fitted to the push rod tube flange and see that it is kept carefully for reassembling.

Unscrew the four cylinder holding down studs from the crankcase (cylinder base) studs and lift them out through the cylinder head.

Remove the cylinder head, preserving the copper gasket which is fitted between the cylinder barrel and head.

When decarbonising we advise leaving the cylinder undisturbed unless there is special reason to take it off.

The piston rings and piston bed into the bore with use and in the ordinary way cylinder removal is only needed when the whole engine is being overhauled.

Removal of Valve Springs and Valves.

Compress the valve springs on one valve with service tool KA163 /2 to expose the valve cotter. Pick off the two halves of the cotter from the valve stem or out of the valve spring collar. Release the springs and remove with the valve spring collar. Take out the valve and mark it so that it is ground in to its own seating and refitted to it. Next remove the other valve and mark. Also keep together the valve springs and cotters, etc., off each valve so that they go back with the valve to which they were originally fitted. Remove and keep aside the valve

spring washers from below the springs.

Decarbonising.

Bring the piston to top dead centre and scrape all the carbon from the piston crown. Use a scraper formed from a piece of copper or brass that will not scratch the piston. Do not in any circumstances rub the piston with emery cloth or anything of an abrasive nature as the particles cannot be prevented from getting between the piston and cylinder where they will cause serious harm.

After cleaning the piston top, push the piston slightly down the bore and wipe away all traces of carbon from the bore. Bring the piston to the top again and wipe carefully round the top land above the rings.

Using the same scraper, clean the exhaust port and the combustion chamber being very careful not to harm the valve seatings. The exhaust port can be rubbed clean with emery cloth, finishing off with fine grade, but if this is used all loose abrasive must be cleaned out, especially from the valve guides. To clean these roll a piece of clean rag round into a thin " pencil " which can be pushed into the guides, picked up at the other end and pulled through.

If a compressed air jet is available this is the ideal method of cleaning.

Refacing and Grinding in Valves.

Clean the valves with emery cloth, finishing off with fine grade, and take care not to touch the stems where these bear in the valve guides, and so reduce the diameter. Each valve should be held by the stem in the chuck of a lathe or driller and rotated at fairly high speed whilst the emery cloth is held against the head and radius below the head. Valves that are badly scaled due to the additives in the present-day fuels should be cleared of scale by using a small piece of carborundum against the scaled parts, finishing off with emery cloth.

Most agents will undertake to reface valves on a valve refacing machine for a small sum. The seat angle is 45°.

The object of cleaning and refacing the valves is to reduce as much as possible the amount of grinding in needed to make them gastight, as it is important not to wear away the seatings in the cylinder head any more than can be helped, owing to the high cost of renewal.

Taking each valve in turn, coat the seating on the valve with a light smear of fine grade valve grinding paste - obtainable from most agents. Some brands are supplied with two grades in one tin — the coarser grade is not usually needed for valves.

Push the valve into the guide and grind it in to the seating by holding the stem of the valve with service tool KA164 /2. The art of good valve grinding lies in rotating the valve only partially, through a few degrees of movement, against the seating, in raising it after every few reversals, and then turning it and grinding further in another position.

This constant change of position distributes the grinding paste evenly, and gives the smooth matt grey surface required. A light coil spring under the valve head is useful as it will lift the valve from the seat when the pressure on the grinding tool is released.

When an even surface is obtained all round the valve seating and the seating in the head, the work is finished, and the other valve can be tackled.

Do not try to get a polished surface, and never rotate the valve round and round against the seating as this forms concentric rings on the seatings which are most unsatisfactory.

The valve seats that are inserted in the aluminium alloy head are made from a very hard material and are very durable. Should they require trueing up after very prolonged service they must be ground true and not cut.

The trueing up can be done with a standard 45° valve seat refacing stone such as is usual equipment in most garages.

Wash the valves in petrol and dry ready for refitting. Wipe out carefully all traces of grinding paste from the seatings and their immediate surroundings.

Refitting Valves and Springs to Cylinder Head.

See that the valves are quite clean, oil the stems sparingly or smear lightly with " Oil Dag " and push through the guides into position.

Place the valve spring washer over the guide, concave (depressed) side upwards, follow up with the inner and outer valve springs and the valve spring collar. Refit the spring compressor KA163 /2 and tighten down the screw, compressing the springs far enough to expose the cotter groove in the valve stem and to allow the split cotter to be fitted. Place the two halves of the cotter in place round the stem with the large ends towards the top of the stem, and the internal rib in the cotter in the cotter groove on the valve. Hold together with finger and thumb and release the compressed springs until the cotter is firmly held in the top washer. A little grease inside the cotters can be used to stick them in place if desired, and this saves holding them whilst releasing the compressor. Remove the compressor, and with a soft mallet tap each valve stem sharply to seat the valve and cotters. The head is now ready to refit.

Refitting the Cylinder Head to the Cylinder Barrel.

See that the joint faces on both the head and the barrel are clean, and place the copper gasket on the top of the cylinder and centralise it on the face.

Make certain that the sparking plug threads in the head and on the plug are quite clear of all particles of carbon, etc.

Those in the head can be cleared by blowing with a jet of compressed air, or the sparking plug can be screwed in temporarily to clear them and the opening into the head wiped clean.

Remove the sparking plug again, and lightly smear the threads with graphite paste or " Oil Dag " before refitting.

Place the cylinder head over the spigot on the cylinder barrel. Refit the cylinder holding down studs, screwing these down into the crankcase studs, and fit the four cylinder head washers and nuts. Tighten these down into light contact with the head, and then continue tightening each in turn a little at a time and in rotation until the head is pulled down firmly

and evenly. Avoid tightening any one nut all at once, and when finishing off, do not tighten excessively.

A good gastight joint is obtainable without forcing the nuts. The tension on the cylinder studs tends to increase as the engine heats up and excessive tightening of the nuts may cause serious damage.

Fit the push rod cover flange joint washers, and guide plate over the studs in the head. Slide the push rod cover up into place and fit the nuts and washers, and tighten. A little jointing compound, such as " Gasket Goo " (manufacturers : The Wilcot Parent Co. Ltd., Fishponds, Bristol) can be smeared over the faces, but must be used sparingly.

Should oil leakage have been observed from the push rod cover gland nut, the nut can be repacked with a thin strand of asbestos string after unscrewing from the push rod cover.

From inside the rocker chamber thread the two push-rods (previously marked) down through the pushrod guide plate and cover engaging the ball ends of the rods in the cups in the bottom rockers.

See that the piston is at top dead centre of compression stroke otherwise the rocker bearing bracket assembly will not fit down on the platform without the valve springs being compressed.

Fit the rocker bearing bracket gasket and bracket assembly to the platform, engaging the ball ends of the rockers with the cups on the push rods.

Be most careful that the push rods are properly engaged with the cam followers and rockers.

When correctly located tighten the three bearing bracket bolts securely. Spin the pushrods to check that they are properly located top and bottom.

Readjusting the Tappet Clearances.

Tappet clearances must be checked and adjusted when the engine is cold. The correct clearances for running, as distinct from those employed when checking the valve timing, are .005-inch on both inlet and exhaust rockers. After decarbonising and grinding in valves, readjustment is essential.

The cams employed in this engine are ground with what is termed " quietening ramps," the purpose of which is to take up and restore the running clearances gradually. Before each tappet is adjusted it is most important that the crank¬shaft is turned and set in a certain position if the adjustment is to be done correctly.

Note specially therefore that before checking or resetting the clearances the camshaft must be turned and set to bring the cams as follows :-

When resetting the inlet clearance the exhaust valve must be on the point of opening, and when dealing with the exhaust tappet the inlet valve must be on the point of closing.

To adjust, slacken the lock nut on the tappet in the rocker end. Turn the tappet by using a spanner on the hexagon head of the tappet below the rocker, turning it clockwise (viewed from above) to decrease clearance, and anti-clockwise to increase it.

One turn of the tappet will alter the clearance by approximately .038 inch.

Check with a feeler gauge and when correctly set hold the tappet firmly with the spanner and with a second spanner tighten the lock nut securely. After tightening the lock nut it is best to check the clearance once more just in case it was inadvertently altered when tightening the lock nut.

Refitting the Rocker Cover, etc.

See that the joint washer is in order, or that a new one is at hand, clean the joint faces and stick the joint washer to one of them with a light smear of grease or " Gasket Goo." Place the cover in position and fit the eight bolts. As previously mentioned there are five different lengths and they must go back in the right places. See illustration.

The longest fits into the hole at the rear of the cover in the centre. Taking them in decreasing lengths the remainder are fitted as follows. Three the same length in the bolt holes on the right side and the hole in the centre at the front. The next shorter bolts (two of the same length) fit in the holes on the left-hand side halfway along.

The next shorter fits in the hole at the left-hand front corner, and the shortest at the left-hand rear corner. Tighten down evenly and firmly. Refit the rocker box oil pipe noting that there are two fibre washers on the top hollow bolt, one at each side of the banjo. Replace the cylinder head steady, carburetter, including throttle and air valves and replace the tank, finally fitting the fuel pipe.

See that the sparking plug is clean and the firing points correctly set, coat the threads lightly with graphite-paste or " Oil Dag " and refit it to the head, tightening it fully.

Refit the silencer and exhaust pipe.