Lubrication.

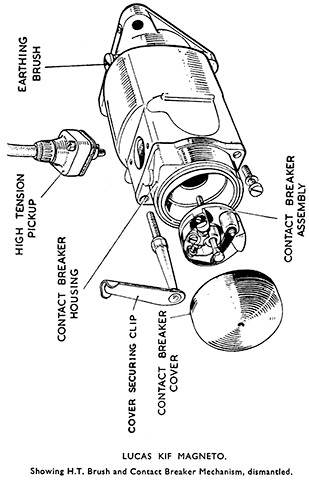

Every 3,000 miles remove the hexagon headed screw from the centre of the tapered shaft and carefully draw off the contact breaker. (Illustration, page 64).

Push aside the rocker arm retaining spring, prise the rocker arm off its pivot, and very lightly wipe over the bearing with clean engine oil. Soak the cam lubricating pad in the contact

breaker housing with thin oil (S.A.E.10).

The cam is lubricated from this pad by a wick through a small hole in the face of the cam. Remove all surplus oil, and take great care not to allow oil to remain on the contacts. Refit the rocker arm and push back the retaining spring. Refit the contact breaker making sure that the projecting key on the tapered portion of the contact breaker base engages in the keyway in the magneto spindle, otherwise the timing will be incorrect. Screw in the hexagon headed pin and tighten gently. Do not use excessive force, but do not leave the pin slack.

The armature bearings are packed with grease during manufacture and attention is unnecessary until the motor¬cycle is due for a general overhaul when it is advisable to have the magneto inspected by a Lucas Service Agent.

Adjustment.

After lubricating as above check the point gap and readjust as needed as follows : Rotate the engine with the kickstart until the contact breaker points are fully

opened. Check the gap with a feeler gauge .012-in. thick.

If the setting is correct the gauge will be a sliding fit between the contacts — adjust if too loose or too tight.

Keeping the contact breaker in the position giving the maximum opening of the contacts, slacken the lock-nut on the adjustable contact screw and turn the screw by its hexagon

head until the gap is set to the gauge. Tighten the lock-nut without moving the adjustable point, and re-check the gap.

Cleaning.

Examine the contacts every 5,000 miles for burning or blackening. Clean them with a fine Carborundum stone, or with fine emery cloth. Wipe away all dust or dirt with a petrol-moistened cloth. This work is of course done when the contact breaker is removed.

Take out the two high tension pick-up screws (Illustration, page 64) and remove the pick-up. Polish the insulation with a fine dry cloth. Check the brush for freedom and wear.

It must work freely in its holder and if worn to within 1/8-in. of the shoulder must be renewed. If necessary clean with a petrol-moistened cloth.

While the pick-up is out, clean the slip ring track and flanges by holding a soft cloth against them by means of a suitably shaped piece of wood inserted through the pick-up

opening. Turn the engine slowly with the kickstart whilst the cloth is held in place.

Replacement of High Tension Cable.

Any sign of perishing, cracking, or other deterioration of the cable insulation indicates that the cable must be renewed by a suitable length of 7 mm. rubber covered ignition cable.

To renew, bare one end of the new cable for about ¼-in., thread it through the knurled moulded nut, and the bared wire through the metal washer removed from the old cable.

Bend back the strands of wire over the washer. Push the wire into the pick-up and screw the knurled nut home. Fit the suppressor from the old cable on to the other end.