Draining Engine Oil. (To be done every 2,000 miles at

the latest.)

Remove the oil tank drain plug—illustration page 50, and drain out all oil. Do this when the oil is hot after a run. Do not disturb any of the oil pipes or the fabric oil filter. If the main oil feed pipe is disturbed and is emptied of oil the oil pump must be primed before running the engine, and the feed must be checked. See page 27.

Refit drain plug. Refill tank to correct level. See page 5.

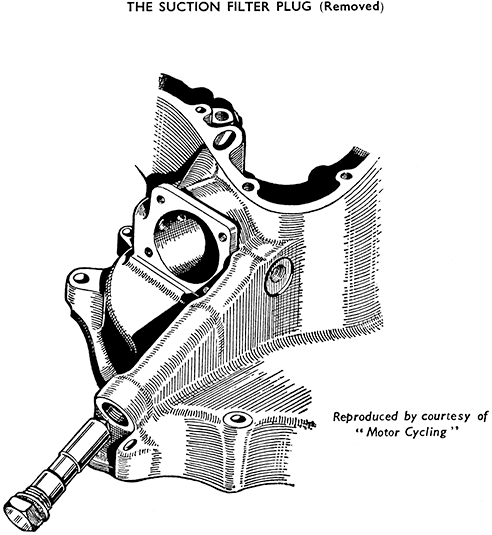

Cleaning Crankcase Suction Filter. (To be cleaned every 2,000 miles.)

The filter plug is screwed into the crankcase at the right-hand rear bottom corner.

The plug fits the crankcase with a very small diametrical clearance which whilst permitting oil to pass, stops anything which could harm the pump.

Remove the filter plug, wash in clean petrol, dry off and refit. See that the plug gasket is in order and tighten fully. See illustration above.

The Ball Valve. The purpose of this valve is to prevent oil running through the oil pump from the tank and flooding the engine when not in use. It consists of a spring loaded ball carried in a body screwed on to the oil strainer assembly which has a seating for the ball. The main oil feed pipe is connected to the ball valve body. Illustration page 23.

It will need attention only if the engine should smoke excessively at the exhaust after standing for some time, or is difficult to start due to an accumulation of oil in the crankcase. Do not therefore remove the ball valve unnecessarily.

Should the ball valve assembly require attention it may be unscrewed from the oil tank using a spanner on the hexagon of the oil strainer assembly.

To take apart hold the oil strainer assembly by the hexagon and unscrew the ball valve body off it. Do not lose the ball, and do not remove the spring from the valve body. Wash all parts in clean petrol, allow them to dry off and examine the seating. If defective fit a new body. Reassemble the parts taking care that the spring is free and that the ball is against the seating in the strainer assembly. After tightening test by blowing from the oil pipe union end to the strainer. end. If air leaks past, the defective parts must be renewed. When satisfactory refit to the oil tank.

Before connecting up the main oil feed pipe make sure that it is filled with oil to prime the pump. To prevent air locks in the pipe loosen the banjo union at the lower end to allow the oil to run through. Tighten the banjo union carefully when the pipe is full and refit the union nut at the top and tighten on to the ball valve body. Check the oil feed. See page 27.

The Fabric Oil Filter. Illustration page 23.

Remove the filter element and fit a new one after 10,000 miles service at the latest. Do not try to clean the dirty element for further use. This is deprecated because during any cleaning process impurities filtered from the oil and caught on the inside of the element cannot be prevented from getting on to the outside and from there into the oil stream.

It is inadvisable to continue using oil which has already been in circulation after fitting a clean element. We advise draining the tank and refilling with clean oil when an element is replaced. The tank should also be cleaned out. The element may be changed and the tank swilled out with clean petrol whilst in position, but it is preferable to take it off. The oil will not run out of the filter chamber or the tank if the tank is kept upright, so it is only necessary to disconnect both feed and return pipes from the tank, remove the top and bottom fixing bolts and detach it from the machine.

Empty the tank of oil, and whilst holding the bottom filter cap and adapter hard against the tank, unscrew the filter stud nut and remove the gasket, top cap, and top cap gasket. Pour out the oil from the filter chamber and pull out the element from the top, also pull away the bottom cap, gasket, and tube assembly. Illustration page 23.

Remove the ball valve assembly and drain plug from the tank and clean out thoroughly by washing in clean petrol. Allow the interior to dry off properly, and refit the ball valve assembly and drain plug.

Push a new filter element into the filter chamber from the top. Fit the bottom cap and gasket over the tube assembly making certain that the tube assembly gasket is also in place, and thread the tube assembly and stud up into the tank through the centre of the filter element.

Hold the bottom cap and adapter firmly in place so that oil will not leak out past the gasket and fill the filter chamber with oil.

Put on the top cap gasket and cap, the stud gasket and nut. Centralize the cap gasket and tighten the stud nut.

Refit the oil tank, and prime the pump by filling the feed pipe with oil before connecting up. Also refit the return oil hose. Refill the tank.

The object of filling the filter chamber is to ensure that the full amount of oil is carried. If it is left empty it will have to fill from the return pump before any oil will be observed reentering the tank through the hole in the top of the filter chamber, and as the chamber fills the level in the tank will be reduced. Check the lubrication system—see next section.

Checking the Lubrication System. This check is essential after re-assembling the oil feed pipe and it is advisable to carry it out before using a new machine for the first time or after an oil change.

After filling the oil tank and priming the pump (see page 26), slacken off the union nut holding the rocker oil feed pipe to the union at the top of the timing cover. Start up the engine and run it slowly. After a few moments' running the oil should issue steadily from the union Allow a few moments more to make certain that the oil is not just that which had been left in the oil passages, and then tighten the union nut. If a steady flow is not obtained after a 30 second run, stop the engine and prime the oil pump once more.