Maintenance. It is inadvisable to tamper with the carburetter if the machine is running satisfactorily, but occasional adjustment of the control cables and cleaning out may be required.

The movement of the twist grip or air lever should cause immediate movement of the appropriate valve with as little lost motion as possible, and of course the controls must be adjusted to allow full closure. The throttle is provided with its own adjustable stop which is independent of the cable adjuster and when adjusting the cable this stop should be set to the slow idling position as explained later.

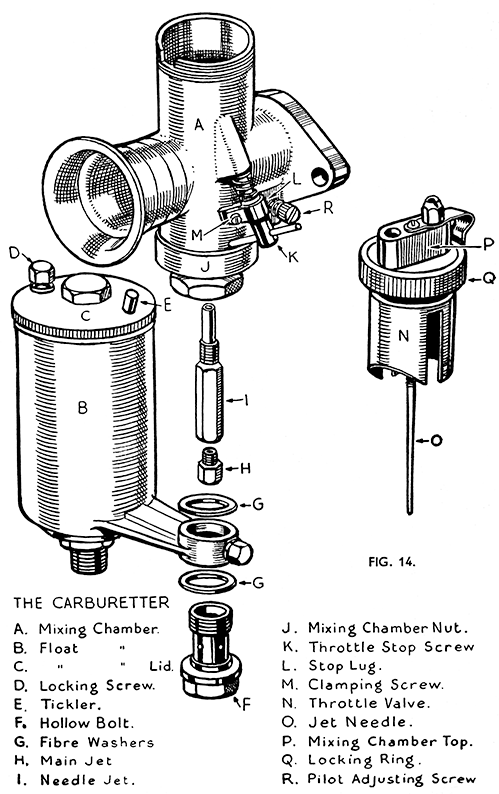

To take out lost motion from the controls screw the cable adjuster anti-clockwise out of the mixing chamber top (P, illustration, page 53).

Symptoms which indicate that the carburetter needs cleaning are : difficult starting, explosions in the silencer on closing the throttle after fast running, and a tendency for the engine to stall in traffic when idling.

Before dismantling the carburetter for cleaning always check the fuel supply first by loosening the feed pipe union nut below the float chamber, and turning on each tap in turn. If the fuel fails to gush out of the pipe the tap strainers are choked and must be cleared, or there is an air lock in the tank due to a choked cap vent hole.

Should the engine " peter out " after a little running, but the carburetter flood properly on depressing the tickler (E) suspect that the air vent hole through the milled edge of the float chamber lid (C) is choked.

Occasional flooding after the feed is turned on may usually be cured without extensive dismantling as follows : Turn off the fuel. Loosen the locking screw (D) and remove the float chamber lid. Half rotate the float needle backward and forward between the thumb and finger whilst holding it up lightly against the needle seating. After a few twists turn on the fuel and check the results. If the fuel does not overflow replace the lid and tighten the locking screw. If ineffective the float chamber will have to be dismantled as a new float or float needle may be required.

Dismantling and Re-assembling. Unscrew the lock-ring (Q) and pull out the throttle and air valves. Remove the fuel pipe and the two flange nuts and washers. Draw the carburetter away from the cylinder head and off the studs. Preserve the special insulating gasket.

Unscrew and remove the hollow bolt (F) which will release the float chamber assembly (B). Retain the two banjo gaskets (G).

Preserve the special insulating gasket.

Unscrew and remove the hollow bolt (F) which will release the float chamber assembly (B). Retain the two banjo gaskets (G).

54

Slacken lock-screw (D) and unscrew the lid (C) from the float chamber. Pinch the spring bow and press the float needle down through the bow and the float, pull it out from the bottom and remove the float. Clean out the fuel passage and float chamber bowl. If the carburetter has been flooding shake the float whilst holding it close to the ear, and if fuel can be heard inside, renew the float.

When reassembling be careful to locate the spring bow on the float properly with the groove in the needle.

To dismantle the mixing chamber assembly, hold the nut (J) firmly in a vice, protecting it from damage by covering the vice jaws with clamps of copper, brass, or aluminium. Unscrew the mixing chamber from the nut by passing a round bar carefully through the choke bore and pulling on it evenly anti-clockwise.

A fibre gasket fits between the nut and the mixing chamber. Retain this. With a small block of wood placed in the top of the mixing chamber tap out the jet block towards the bottom. When it is out unscrew the main jet (H) from the needle jet (I) and the latter from the jet block. Also remove the pilot air bleed screw (R).

Clean all parts by washing in petrol and blow all passages clear. A compressed air jet is best, but a small jet which will work quite well may be made quite easily to fit the tyre inflator.

When reassembling push the jet block home engaging the dowel in the slot in the mixing chamber, and be most careful not to shear off the needle jet or main jet by overtightening. Replace the gasket and screw the mixing chamber firmly into the nut. Reassemble the remainder of the carburetter and refit to the engine. Do not overtighten the flange nuts or the carburetter flange face may distort.

Adjusting the Carburetter. There is generally nothing to be gained by varying the jet and needle settings from standard except that after very prolonged use the needle jet may become worn and enrich the mixture over a large amount of the range of throttle opening. In such circumstances the needle may be detached from the throttle valve and replaced with the clip in the next higher groove. Normally the needle clip is in the middle groove.

Screw the pilot air bleed screw fully home, and then reset it out again one and a half turns. Start the engine and after it has warmed up a little set the throttle stop screw (K) so that the engine runs too fast for idling with the twist grip closed. If necessary slacken the small screw (M) to free the stop lug (L).

Gently screw out the stop screw until the engine slows down and begins to falter, and then adjust the pilot air bleed screw in or out a trifle to make the engine run regularly and faster. Gently screw out the stop screw a little more until the running is slower and faltering occurs again. Tighten the locking screw (M) with the lug (L) set in contact with the mixing chamber in the position illustrated. Now adjust the pilot air bleed again to get the best slow running. If this second adjustment makes the engine run too fast go over the job again. Finally tighten the locking screw (M) without altering the setting of the lug on the screw.

Avoid an over-rich pilot setting as this will cause heavy fuel consumption, particularly if much running is done at small throttle openings.

Erratic slow running may be due to air leakages, or if a large mileage has been covered, to a worn throttle valve.