THE CARBURETTER

Description and Explanation of Working.

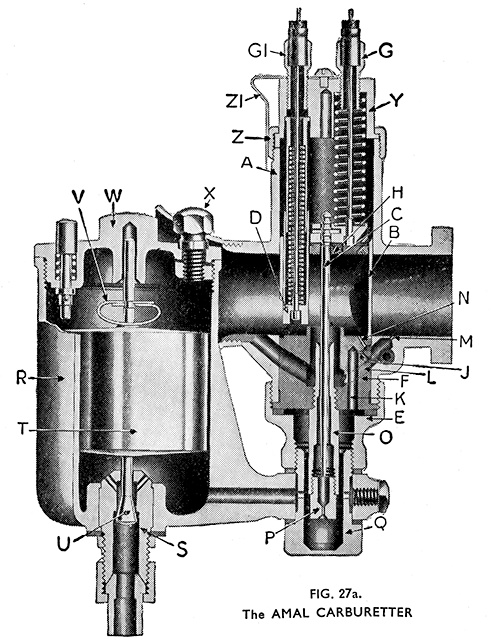

The illustrations should be referred to for explanation of the following sections. The purpose of the carburetter is to atomise the correct amount of fuel with the air that is induced into the engine, and thus supply a correctly-proportioned mixture at all speeds within the engine's range at all throttle settings.

This is achieved by the selection of the correct size main jet, and main choke bore, in conjunction with the right adjustment or setting of the jet needle and the pilot jet.

The volume of mixture, and therefore the power, is controlled from the handlebar twist grip which causes the throttle valve in the carburetter to be raised or lowered, and the correct setting of the carburetter provides the right mixture at all positions of the throttle valve.

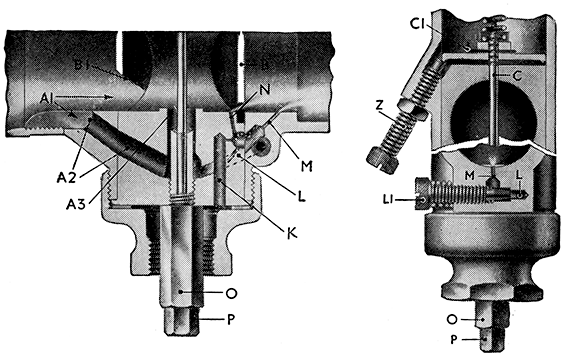

The opening of the throttle brings into action first the mixture supply from the pilot system, for idling at slow speed, through the pilot outlet (M). The further progressive opening of the throttle admits air via the main intake and reduces the depression on the pilot outlet (M), but in turn a greater depression is created on the pilot by pass (N) causing the mixture to flow from this opening as well as from the pilot outlet. At about 8th of the throttle opening more air is admitted and the mixture is augmented from the main jet (P). The throttle valve cut-away governs the mixture strength from this position of the throttle to about ¼ open. Proceeding up the throttle range the mixture strength is controlled from about ¼ to ¾ open by the position of the needle (C) working within the needle jet (0). The main jet does not spray directly into the mixing chamber, but discharges through the needle jet into the primary air chamber, and the discharge goes from there as a rich fuel-air mixture through the primary air-choke into the main air-choke. This primary air-choke has a compensating action.* After about ¾ throttle opening the main jet is the only regulation. It will be understood from the foregoing that as the main jet only exercises a regulating effect on the mixture strength after the throttle is opened ¾ of its travel or over, the fitting of a smaller main jet for economy purposes is useless, and can only cause overheating due to excessively lean mixtures at high speeds. As the mixture strength over the greater portion of the throttle range is controlled by the setting of the needle within the needle jet, cases of excessive fuel consumption are usually capable of improvement by adjustment of the needle setting (referred to later) or by replacement of the needle jet and /or needle because of wear on these components.

|

|

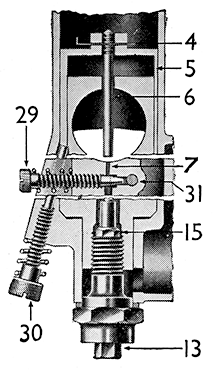

| FIG 27 Section through mixing chamber showing air valve and throttle closed. |

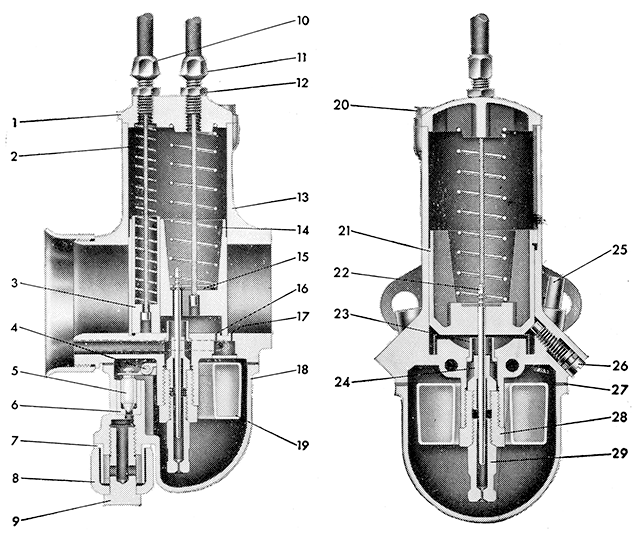

FIG 28 Section through float chamber |

A separately operated mixture control is also provided by the air valve, operated from the handlebar, for use when starting from cold, and until the engine is warm enough to accept the full air supply. This air control partially restricts the passage of air through the main choke

THE CARBURETTER (MONOBLOC TYPES). Petrol Feed (verification).

Later models are fitted with a filter gauze at the inlet to the float chamber. To remove the filter gauze unscrew the banjo bolt (22), the banjo can then be removed and the filter gauze withdrawn from the needle seating. Ensure that the filter gauze is undamaged and free from all foreign matter. Before replacing banjo turn on petrol tap momentarily and see that fuel gushes out.

* On Monobloc types there are bleed holes in the needle jet which serve the double purpose of air compensating the mixture from the needle jet and allowing the fuel to provide a well outside and around the jet which is available for snap acceleration.

Flooding may be due to a worn needle or a leaky float, but nearly all flooding with new machines is due to impurities (grit, fluff, etc.) in the tank — so clean out the float chamber periodically till the trouble ceases. If the trouble persists, the tank might be drained, swilled out, etc.

|

|

|

| FIG. 28a. SECTION THROUGH NEEDLE JET AND PILOT PASSAGE. |

SECTION THROUGH STOP SCREW AND PILOT JET. |

Re-assembling (after dismantling)

See that the washer on the bottom of the jet block is in good condition, otherwise fuel will leak across its face causing rich erratic running, if the washer is faulty it should be replaced by a new one. When replacing the throttle see that the jet needle goes into the centre hole in the jet block and once in, note the throttle works freely when the mixing chamber cap (2) is screwed down firmly and held by spring (18).

When re-assembling the float see that the narrow leg portion of its hinge is uppermost, as this operates the needle. Care should be taken to see that the joint faces of the side cover and body are not damaged or bruised and that the joint washer is in good condition, otherwise difficulty will be experienced in making a petrol tight joint.

Cable Controls.

See that there is a minimum of backlash when the controls are set back and that any movement of the handlebar does not cause the throttle to open. The adjusters are on the top of the carburetter. See that the throttle shuts down freely.

Adjust in the following order.

Note. The carburetter is automatic throughout the throttle range—the air valve should always be wide open except when used for starting or until the engine has warmed up. We assume normal petrols are used.

Read remarks on pages 65 and 66 for each tuning device and get the motor going perfectly on a quiet road with a slight up gradient so that on test the engine is pulling.

|

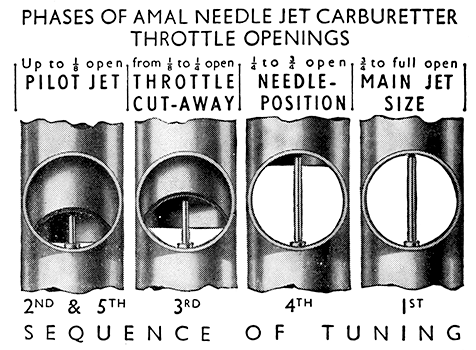

| FIG 29 |

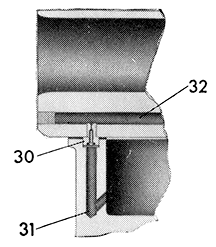

1st Main Jet with throttle in position 1 (Fig. 29).

If at full throttle the engine runs " heavily " the main jet is too large.

If at full throttle by slightly closing the throttle or air valve the engine seems to have better power, the main jet is too small.

With a correct sized main jet the engine at full throttle should run evenly and regularly with maximum power.

If testing for speed work ensure that the main jet size is sufficient for the mixture to be rich enough to keep the engine cool, and to verify this examine the sparking plug after taking a fast run, de-clutching and stopping the engine quickly. If the plug body at its end has a cool appearance the mixture is correct : if sooty, the mixture is rich : if however there are signs of intense heat, the mixture is too weak and a larger main jet is necessary.

2nd. Pilot Jet (Fig. 29). with throttle in positions 2 and 5.

With engine idling too fast with the twist grip shut off and the throttle shut down on to the throttle adjusting screw, and ignition set for best slow running : (1) Screw out throttle adjusting screw until the engine runs slower and begins to falter, then screw pilot air adjusting screw in or out, to make engine run regularly and faster. (2) Now gently lower the throttle adjusting screw until the engine runs slower and just begins to falter, adjust the pilot air adjusting screw to get best slow running ; if this 2nd adjustment makes engine run too fast, go over the job again a third time.

3rd. Throttle Cut-away with throttle in position 3 (Fig. 29).

If, as you take off from the idling position, there is objectionable spitting from the carburetter, slightly richen the pilot mixture by screwing in the air screw sufficiently, but if this is not effective, screw it back again, and fit a throttle with a smaller cut-away. If the engine jerks under load at this throttle position and there is no spitting, either the jet needle is much too high or a larger throttle cut-away is required to cure richness.

4th. Needle with throttle in postion 4 (Fig. 29).

The needle controls a wide range of throttle opening and also the acceler¬ation. Try the needle in as low a position as possible, viz., with the clip in a groove as near the top as possible ; if acceleration is poor and with air valve partially closed the results are better, raise the needle by two grooves ; if very much better try lowering needle by one groove and leave it where it is best. If mixture is still too rich with clip in groove No. 1 nearest the top—the needle jet probably wants replacement because of wear. If the needle itself has had several years' use replace it also.

5th. Finally go over the idling again for final touches.

Do not adjust the carburetter to get a very slow tick over, since such a setting will involve the throttle valve having to be opened much further to start from cold, and the consequent reduction of the depression on the pilot system will weaken the mixture and starting will become difficult.

In cases where difficulty is encountered set the throttle stop screw to give a reasonably fast idling speed by screwing the adjuster a little further in. Set the pilot air-bleed screw to give a slightly rich mixture by also screwing it inwards (clockwise) a trifle.

Tracing Faults.

There are only two possible faults in carburation, either richness or weakness of mixture.

Indications of :

| Richness. | Weakness. |

| Black smoke in exhaust. Petrol spraying out of carburetter. Four strokes, eight-stroking. Two strokes, four-stroking. Heavy, lumpy running. Sparking plug sooty. |

Spitting back in carburetter. Erratic slow running. Overheating. Acceleration poor. Engine goes better if :—

|

| If richness or weakness is present, check if caused by :— | |

| (1) Petrol feed. |

Check that jets and passages are clear. that filter gauze in float chamber banjo connection is not choked with foreign matter, and that there is ample flow of fuel. Check there is no flooding. |

| (2) Air leaks. | At the connection to the engine or due to leaky inlet valve stems. |

| (3) Defective or worn parts. | As a loose fitting throttle valve, worn needle jet, loose jets. |

| (4) Air cleaner being choked up. | |

| (5) An air cleaner having been removed. | |

Removing the silencer or running with a straight through pipe requires a richer setting.

Having verified the correctness of fuel feed and that there are no air leaks, check over ignition, valve operation and timing. Now at throttle position shown on page 66, fig. 29, test to see if mixtures are rich or weak. This is done by partially closing the air valve, and if engine runs better weakness is indicated, but if engine runs worse richness is indicated.

To remedy, proceed as follows :—

| To cure richness. | To cure weakness. | |

| Position 1. | Fit smaller main jet. | Fit larger main jet. |

| Position 2. | Screw out pilot air adjusting screw. | Screw pilot air adjusting screw in. |

| Position 3 | Fit a throttle with larger cutaway (para. F, page 66). | Fit a throttle with smaller cutaway (para. F, page 66). |

| Position 4. | Lower needle one or two grooves (para. E, page 66). | Raise needle one or two grooves (para. E, page 66). |

Note. It is not correct to cure a rich mixture at half throttle by fitting a smaller main jet because the main jet may be correct for power at full throttle : the proper thing to do is to lower the needle.

Fixing Carburetter.

Erratic slow running is often caused by air leaks, so verify there are none at the point of attachment to the cylinder or inlet pipe—check by means of an oilcan and eliminate by new washers and the equal tightening up of the flange nuts. On later models a sealing ring is fitted into the attachment flange of the carburetter. Also in old machines look out for air leaks caused by a worn throttle or worn inlet valve guides.

Banging in Exhaust may be caused by too weak a pilot mixture when the throttle is closed or nearly closed—also it may be caused by too rich a pilot mixture and an air leak in the exhaust system ; the reason in either case is that the mixture has not fired in the cylinder and has fired in the hot silencer. If the banging happens when the throttle is fairly wide open open the trouble will be ignition—not carburation.

Bad Petrol Consumption of a new machine may be due to flooding, caused by impurities from the petrol tank lodging on the float needle seat and so prevent its valve from closing. Flooding may be caused by a worn float needle valve. Also bad petrol consumption will be apparent if the needle jet (15) (see Fig. 27) has worn ; it may be remedied or improved by lowering the needle in the throttle, but if it cannot be—then the only remedy is to get a new needle jet.

Air Filters.

These may affect the jet setting, so if one is fitted afterwards to the carburetter the main jet may have to be smaller. If a carburetter is set with an air filter and the engine is run without it, take care not to overheat the engine due to too weak a mixture ; testing with air valve (page 66), will indicate if a larger main jet and higher needle position are required.

Effect of Altitude on Carburetter.

Increased altitude tends to produce a rich mixture. The greater the altitude, the smaller the main jet required. Carburetters ex-works are set suitable for altitudes up to 3,000 feet approximately. Carburetters used constantly at altitudes 3,000 to 6,000 feet should have a reduction in main jet size of 5 per cent, and thereafter for every 3,000 feet in excess of 6,000 feet altitude further reductions of 4 per cent should be made.

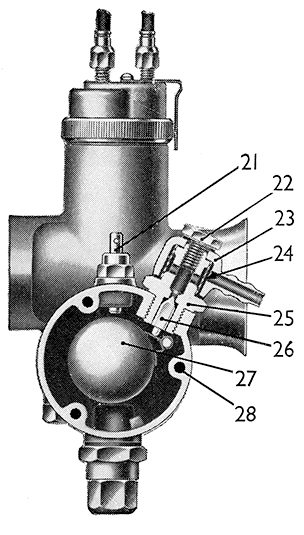

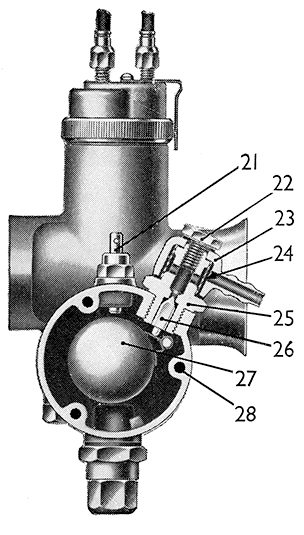

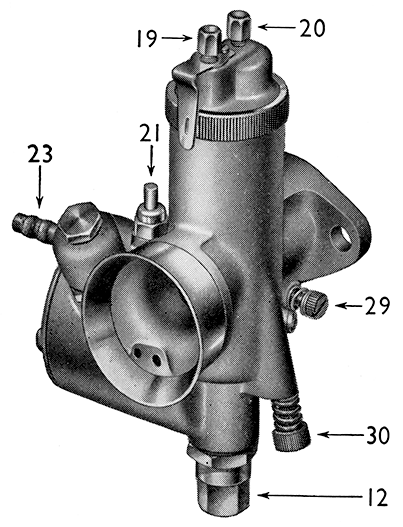

| THE AMAL MONOBLOC CARBURETTER (External View) |

|

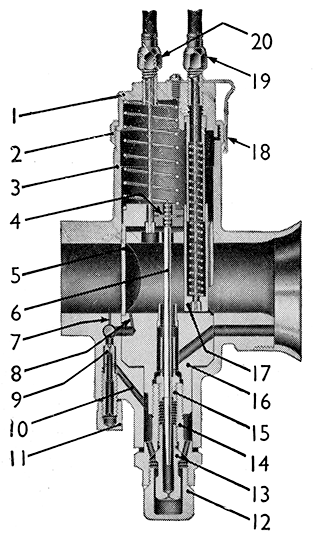

T.T. CARBURETTER.

Note.—The method of adjusting the T.T. Carburetters fitted to Scrambler and Clubman models is similar to that detailed for the standard Monobloc instruments, except that the pilot adjuster is turned clockwise to weaken the mixture. The procedure for dismantling also differs. For full details see Amal List No. 374 obtainable from the Carburetter makers.