Sparking plugs are produced in many types, each type having different characteristics apart from differences in thread diameter and length of thread (reach). In no circumstances must a shorter reach plug be fitted. The types recommended later are 14 mm. diameter thread by 18 mm. reach (extra long reach) and have heat resistance characteristics to suit the engine.

Suitable plugs for MSS are: Champion NA8 ; K.L.G. FE80, Lodge H.L.N. For Viper and Venom use Champion NA10, K.L.G. FE100, Lodge 3HLN. Other types should not be used without advice from us or one of our Agents.

The use of a sparking plug of lower internal heat resistance will cause harm to the engine due to pre-ignition through overheating, conversely a plug having too high internal heat resistance will cause difficulty in starting, bad slow running, and will tend to misfire and cut out entirely due to oiling up.

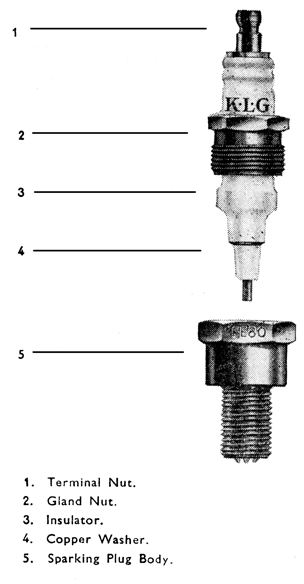

Sparking Plug Maintenance. Some sparking plugs are made so that they can be taken apart for cleaning and are known as "detachable types." These are cleaned when necessary by unscrewing the gland nut (2 Illustration, page 60) from the plug body (5) making it possible to pull out the insulator and electrode (3).

THE KLG TYPE FE80 SPARKING PLUG*

Used on MSS only. See note above

If a special plug detacher is not available the plug is best held inverted in a vice by the gland nut and the body screwed off the nut. Care is needed not to damage the nut and it should be protected by clamps on the vice jaws. Preserve the seating copper washer (4) carefully for refitting.

The inside of the body can be scraped clean with a narrow blade and the centre electrode and interior insulation brushed with a wire brush or cleaned with emery cloth. Before reassembling, oil the copper washer very sparingly with thin oil, verify that it seats properly in the plug, insert the insulator and screw home the gland nut tight.

"Non-detachable" types are best cleaned with a small wire brush, afterwards washing in petrol. A useful wire brush is easily made from a short length of copper tube about ¼-in. bore and some lengths of discarded control cable. To make it; heat the tube dull red and plunge it into cold water. Push as many lengths of cable into the tube as the bore will take. With this end of the tube resting on a firm metal surface (the top of a vice) hammer the copper flat over the control wires. Cut off the wires with a sharp chisel about ½-in from the end of the tube, and allow them to

unstrand or fray out.

Alternatively these plugs can be cleaned by the sandblast method and most Service stations are equipped with sparking plug cleaners working on this principle. If this method is used very great care indeed must be taken to remove thoroughly all traces of sand from inside the gas space of the plug. The sand is often found to lodge up inside between the insulator and the body and proper washing out with petrol and blowing over an air jet are essential to get rid of it. The need for this cannot be overstressed as should sand work down into the cylinder considerable harm will be done very quickly.

Adjusting the Spark Gap. Do not in any circumstances try to adjust by bending the centre electrode as this will crack the insulator. Resetting is done by bending the side electrode, and the gap should be .018-in. to .023-in.

Note.—The instructions above for cleaning apply only to plugs having ceramic insulators. Mica insulation must not be abraded by emery cloth, wire brushes, or sand blasting.