Some Models were fitted with KLG type 902 plugs, with mica insulation.

WARNING.

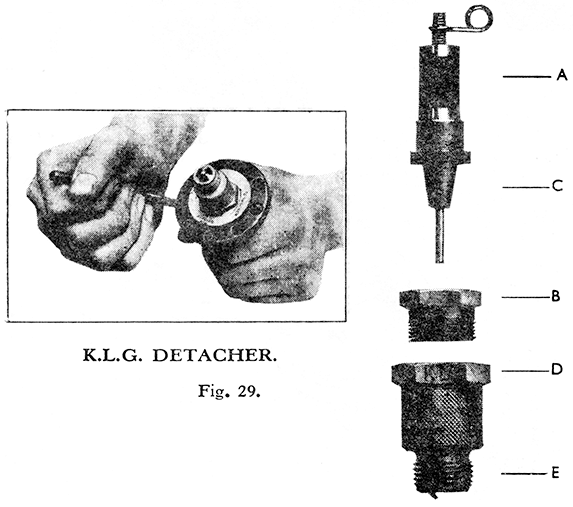

The procedure detailed for plugs with Corundite insulators does not apply to any sparking plug which may be fitted, and which has mica insulation. Mica insulation will be ruined if the plug is either sand blasted or the insulation is cleaned with emery cloth. The insulation of such plugs must only be cleaned by soaking in paraffin or petrol and wiping with rag. The Corundite insulation can be cleaned on a sandblast cleaner, but it is usually satisfactory to do so by hand. First unscrew the gland nut from the body so that the insulated centre electrode may be withdrawn. If the Corundite insulation is oily, first wash it in petrol or paraffin then using fairly coarse emery cloth, remove the carbon deposit, then wash again. The firing point of the centre electrode should be cleaned with fine emery cloth.

The plug body should be scraped clean internally with a knife or wire brush and finally rinsed in petrol.

Lightly smear the internal washer with thin oil and verify that it is seating properly in the plug body before inserting the central electrode and re-assembling the plug. Care should be taken not to overtighten the gland nut when screwing up the body.

The gap should now be adjusted to .015-in.—.018-in. If the gap is too wide the necessary adjustment must be made by bending the earth point. The firing point of the central electrode must not be levered towards the earth points.