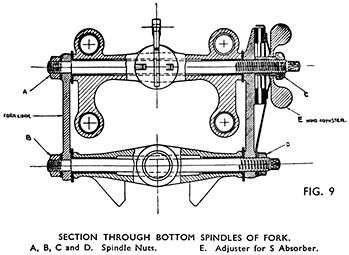

See Fig. 9

See that the adjustment of the shock absorber is slacked right off before checking or resetting the adjustment of the fork spindles.

The final adjustment of the spindles must a low perfect freedom of movement of the fork spindles with no noticeable end clearance between the inner faces of the links, the spacing washers, and the faces on the top-clip, column, and girder cross-members. If on checking the adjustment one spacing washer on each spindle can be turned with the finger and thumb and has no side tilt the adjustment of the particular spindle is correct. Adjustment is needed when the washers are loose and can tilt.

Reference to the illustration will show that the spindles are reduced in diameter on the nearside ends and fit into unthreaded holes in the nearside links into which they are secured by the nearside spindle nuts.

The offside links and offside ends of the spindles are threaded so that the distance between the inner faces of the links is variable by turning a spindle in the links.

To take up play loosen the nut on the nearside of the spindle that needs adjustment, and then the nut on the offside. Grip the square offside end of the spindle with a moveable spanner and turn the spindle anti-clockwise slightly until the play is nearly all taken up. Tighten up both nuts fully and check as described above. If too tight loosen the nuts again and turn the spindle slightly clockwise. Tighten nuts and check again. All four spindles adjust in a similar manner.

Early pattern forks have shock-absorbers at both sides. The spindles on these are adjusted in just the same way.