Service Guide (Red Book)

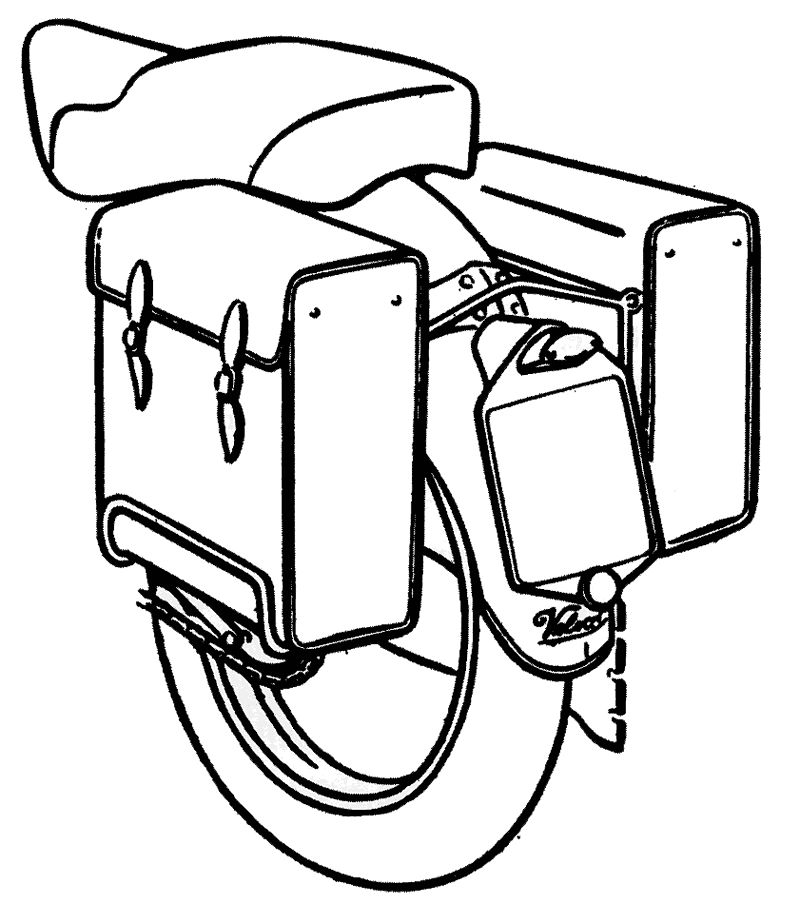

The panniers that are obtainable from the Service Department have tubular frames specially designed to fit the Velocette frame, and they do not depend for security upon clip fixings. The illustration Fig. 42 shows them fitted.

To fit, remove both rear mudguard stay bolts, distance pieces, and aluminium end caps from the rear suspension brackets. Remove pillion footrests. The distance pieces are discarded.

Offer up one pannier frame into place pushing the tube into the end of the bracket. On early models the aluminium caps will require filing to clear the pannier frame tube and allow it to fit flush against the bracket with the pannier tube in position. Secure the tube by fitting the mudguard stay bolt and attach the bottom of the pannier to the pillion footrest lugs with the footrest pivot bolts, or if pillion footrests are not fitted, by the silencer fixing bolt on the right and an extra similar bolt SL111/2 on the left. A nut SL56/27 will also be needed.

Fit the other frame and attach the cross bracing tube with the bolt: provided and finally tighten up all bolts securely.

The luggage grid (also obtainable as an extra) fits to the panriier frames and cannot of course be used without them.

Enamelled and Bare Metal Parts.

Aluminium parts, such as the engine and gearbox, can be cleaned with paraffin and a stiff brush, and afterwards with petrol. These parts are best cleaned before the enamel is tackled.

Accumulated road dirt and mud must never be rubbed or brushed off dry from enamelled parts as the abrasive nature of the dirt will scratch and dull the surface of the enamel.

Always wash off dirt by means of liberal supplies of water, if possible from a hose pipe, but do not employ a high pressure jet. The water should be set to run at a slow rate so that it does not penetrate where it can do harm, such as into the brakes or items of the electrical equipment and carburetter.

Use a soft cloth or sponge to mop off the dirt when it is properly loosened by the water.

If water is used from a bucket a little household detergent washing powder (such as “ Tide ") may be mixed with the water and will help to remove oil or grease.

Dry off with a leather and polish with one of the many polishes s now on the market. Chemico “49 " (Makers : The County Chemical Co,, Ltd., 561, Stratford Road, Shirley, Birmingham) will give a high finish which remains waterproof for quite a good time. Proprietary polishes, however, are not a substitute for cleaning and will not give a proper finish unless the surface is properly cleaned first.

Chromium-plated Parts.

All plating is porous, and although Nickel and Chromium are rustless, the surfaces of plated ferrous parts will deteriorate if neglected and left exposed to the weather. Eventually the metal rusts underneath the plating.

Whilst still clean, the plated parts on a new machine should have a rust preventative rubbed in. To avoid leaving them unpleasantly greasy, the excess can be wiped off after application. A proportion of it will have penetrated the pores in the plating.

For this we recommend ‘ Rust Veto Amber X ' and it can be obtained in small tins from the Service Department or Velocette Dealers.

To clean the plating wash off dirt and grit with ordinary soap and water. Never rub off dirt that has dried on. Dry off thoroughly after cleaning and polish with a good non-abrasive Chrome Cleaner. We find that ‘ F.L.P.' supplied by G. H. White, Lowestoft Road, Gorleston, Norfolk, is most satisfactory, and will remove ‘pits’ and discolouration from neglected plating.

After cleaning rub in ‘Rust Veto’ and allow it to set before wiping off the excess.

Maintenance.

Regular checking of tyre pressures is essential for good mileage to be obtained from the tyres. Under inflation, particularly, is very destructive to the casings, and by increasing the rolling resistance tends to increase the fuel consumption.

It should be noted when refitting a cover, or fitting a new one that on some makes the walls are marked to indicate how the cover should fit in relation to the rim. A white spot on the wall must line up with the valve to keep the wheel in balance.

Periodically the tyres should be inspected with the object of removing from the treads any sharp Hints or other foreign bodies which may have become embedded in the rubber. Their removal is made easier if the tyre is partly deflated before attempting to prise them out.

Damage to the tyre casing and the tube may often be avoided by the removal of these potential puncture makers.

<a name="general_tyres_inflation" />The minimum pressures for 3.25 X 19 tyres are 18-lbs. front and 24-lbs. rear. and are sufficient for a solo rider of average weight.

These recommended inflation pressures are based on a rider's weight of 170-lb. If the rider’s weight exceeds 170-lb. increase tyre pressure as follows :

Front tyre: Add 1-lb. per sq. in. for every 28-lb. increase in weight above 170-lb.

Rear tyre: Add 1-lb. per sq. in. for every 14-lb. increase in weight above 170-lb.

If additional load is carried in the form of a pillion passenger or luggage the actual load bearing upon each tyre should be determined and the pressure increased in accordance with the Manufacturer's Load and Pressure Schedule.

The transfers are printed on duplex paper, i.e., one sheet as a guide to place the transfer in position, and the other as a support to the transfer. These two sheets must be separated before transferring. They can be divided by rubbing a corner of the transfer.

Before complete separation is made apply a very thin and even coat of adhesive varnish to the face of the transfer. Keep as closely as possible to the lines of the design so as not to overlap. Allow this varnish to set until it becomes very tacky and then place the transfer in the required position on the article.

Press the transfer down evenly and firmly, and drive out all air bubbles, by rubbing with a soft cloth rolled into a ball, commencing from the centre and working towards the edges. Then with a damp (not wet) sponge or wash leather press down again, taking care not to shift the transfer. It is absolutely essential that the transfer should be in direct contact with the surface in every part. When this is certain apply water freely by means of a wet sponge, and when the paper support is well soaked, lift it up by one corner and peel or slide it off. Then press the transfer down again to make sure it is fully in contact.

After doing this, sponge with clean water in order to remove the composition remaining on the surface of the transfer. This is an extremely important detail, as unless it is properly done the transfer will crack.

To remove traces of superfluous adhesive varnish around the transfer, use a wet sponge to which has been added a little paraffin. Then quickly wipe it off with a damp wash leather, away from the centre.

When the transfer is perfectly dry on the article (usually about 24 hours) it can be varnished to add to its lustre. It must NOT be varnished directly it is transferred.

More Articles …

Subcategories

Scrambler Model Special Instructions

In most respects the methods of adjustment, and maintenance needed to certain parts of the Scrambler do not differ from those employed for the standard model. The standard instruction literature can be taken to apply therefore unless special reference is made, and other instructions given in this section.