Removal of Fuel Tank. Turn off both taps, disconnect the pipes from them, taking care to hold the taps with a second spanner when loosening the pipe union nuts in case the taps turn and the pipe twists.

Take off the bracing strap from the threaded pummels underneath the tank at the front. Remove the tank fixing bolts at the front, slacken the rear one and lift off the tank.

Removal of Rocker Box Assembly. Remove the spark¬ing plug. Take off the rocker oil feed pipe by disconnecting it from the timing cover and removing the banjo union hollow bolt at the top. Remove the rocker cover at the right-hand side, and the two nuts and washers from the fixing studs through the push rod cover top flange.

Rotate the crankshaft by means of the kickstart and observe the movement of the rockers. Turn until the inlet rocker and push rod are seen to rise and then fall. The piston will now be rising on the compression stroke. Note its position through the sparking plug hole and turn until it reaches the top. The two valves will now be closed. This is essential before loosening the rocker box bolts.

Slacken off all nine rocker box bolts in sequence and each a little at a time until quite free. Do not slack off one or two fully leaving the remainder tight.

Raise the rocker box assembly until the push rod cover flange studs are pulled out clear of the holes in the cylinder head.

Working from the right-hand (timing) side of the machine hold the rocker box up clear of the head, and swivel it round, with the push rods as centre, in a clockwise direction towards the front until it is across the machine--at right angles to its original position. It will now be possible to lift it off clear of the projecting push rods.

Removal of Cylinder Head Assembly. Lift out the push rods, marking them as removed so that they are not interchanged when reassembling. Wet indelible pencil is suitable. The inlet is that nearer the cylinder. Do not lose the loose cups at the top of the push rods.

Unscrew and remove the hollow bolts securing the rocker box oil drain pipe to the head and push rod cover, retaining the gaskets. Take away the pipe.

Telescope the upper push rod cover into the lower section and preserve the two gaskets, and push rod guide plate from the upper flange.

Slacken off each of the cylinder head nuts a little at a time in sequence until clear of the head, and take them off. If any of the studs screw out with the nuts they can be separated later. Unscrew any studs left in place by using a screwdriver applied to their top ends.

Lift the cylinder head off the barrel preserving the joint gasket.

It is best to leave the cylinder in place so do not disturb it.

Decarbonising. If the carbon is scraped from the cylinder head before the valves are taken out there will be no chance of marking the valve seatings. Scrape all the carbon away using a scraper of brass or aluminium that will not scratch the surfaces of the combustion space and piston crown.

It will be possible to remove most of the carbon from the exhaust port but final cleaning will be necessary after removing the valves. The ports can be cleaned and polished using emery cloth.

Do not use emery cloth or other abrasive on the piston crown, and after cleaning it lower it a little in the cylinder and wipe all traces of carbon dust off the cylinder wall. Bring the piston back to the top after wiping clean.

Removal of Valves and Springs. Fit a spring compressor (Service Tool KA163/2) over the edge of the cylinder head with the forked end resting on the valve spring collar and the screw in the centre of the valve head. Tighten down the screw until the valve split cotter is exposed and accessible for removal, and take out the two halves. Release and remove the compressor, pull out the valve and remove the springs and their top and bottom washers.

Both valves are dealt with in the same way.

The inlet and exhaust valve springs, collars, and washers are identical, but after they have been in service should not be interchanged. They should, therefore, be marked or kept aside in separate boxes until wanted for refitting.

The split cotters and valves are not interchangeable.

Refacing the Valves and Grinding in. To avoid lengthy grinding in, and the consequent needless wearing of the valve seats in the head, it is recommended that the valves be refaced and polished on a valve refacing machine. These machines are standard equipment at most Agents' workshops, and the small charge made for refacing is always worth while. Alternatively the work can be done with a superfine file and emery cloth if a small lathe or drilling machine is available to hold and rotate the valves.

Badly scaled exhaust valves can be cleared of scale by using a piece of carborundum to rub it off. Finish off and polish finally with fine emery cloth. The seat angle is 45°.

Polish the valve heads and the radii under the heads, but be most careful not to remove any metal from the valve stems.

Deal with the valves one at a time and coat each seating lightly with valve grinding paste. The fine grade is usually best.

Push the valve into place and grind it in by holding the stem in a collet or valve grinding tool. Tool No. KA164 fits the exhaust, and KA164/2 the inlet valve.

The art of good valve grinding lies in rotating the valve against the seating backwards and forwards a few degrees of movement only whilst light pressure is kept upon it, and frequently lifting it off the seating. After each lift, the valve should be brought down into another position to distribute the grinding paste evenly. The constant change of position avoids the formation of concentric lines and grooves on the seating and gives a smooth matt surface free from pit marks. Do not try to get a polished seating and do not grind in valves by rotating them fully in one direction only.

A light coil spring threaded over the valve stem against the radius under the valve head will be found useful to lift the valve off the seat as the work progresses.

Both valves are treated in the same way.

Refacing the Cylinder Head Valve Seats. This work is not likely to be required until a very big mileage has been run, and should be entrusted to a Service Agent. The valve seat material is very hard and refacing can only be done satis¬factorily using a standard 45° Valve refacing stone. They cannot be recut with the normal type of cutter as used for cast iron cylinders and heads.

Refitting the Valves and Valve Springs. Make sure that all traces of carbon dust and grinding paste have been cleaned from the combustion head, seatings, and ports. If possible wash the cylinder head, valves, springs, and collars, etc., in clean petrol and allow them to dry off.

Roll a little clean rag into a " pencil " and push or draw it through the valve guides to clean them out.

Assemble the hairpin valve springs into the bottom collars and fit the bottom collar with springs over the appropriate valve guide. The closed ends of the valve springs overlap each other. Spread a little clean oil or graphite grease over the valve stem and fit the valve through the guide.

Place the valve spring collar and inner rotating collar over the end of the valve stem and locate the ears of the collar over the valve springs.

Place the spring compressor as when dismantling and compress the valve springs until the groove in the valve stem is visible through the collar and there is enough room to fit the split cotter.

A little grease inside the cotter will cause it to stick to the stem and prevent it becoming dislodged when the springs are released.

Fit the cotter - small end towards the valve guide - locating the inner projecting lip with the groove in the valve stern. Release the compressor, meanwhile centralizing the collars and making certain that the cotter is in place. Take away the compressor and fit the other valve in the same way.

Refitting the Cylinder Head Assembly. Clean the piston crown and the top face joint on the cylinder barrel. Also make certain that no carbon dust remains on the cylinder bore or in the sparking plug threads. It is a sound plan to fit the sparking plug at this stage as the action of screwing it in will dislodge anything left in the threads and this can be cleaned off before the head is fitted.

Verify the condition of the cylinder head gasket and if necessary renew it. Place the gasket centrally in place. Wipe round the seat in the head and fit the head into position over the spigot. Line it up so that the stud holes register with those in the barrel.

Thread the four long cylinder studs down through the cylinder head and barrel and screw them into the cylinder crankcase studs using a screwdriver in the slots at the tops of the studs.

Fit the stud washers and Nylock cylinder head nuts. Note that these are special nuts and other types of nuts must not be used to replace them.

Tighten down carefully, a little at a time, and in sequence. That is, do not tighten one nut fully, leaving others slack, but work on each in turn working round them until all are tight.

Do not force the nuts. A good gastight joint is obtainable without excessive tightening. The tension on the studs increases as the engine parts get hot so that over-tightening in the first place will cause serious harm.

Refitting the Rocker-box Assembly. Fit the push-rod guide plate and the two joint gaskets between the flange of the top push-rod cover and the cylinder head. The guide plate fits between the two gaskets. Locate the plate approxi¬mately in its correct relation to the flange. Fit the push rods, guiding them down through the holes in the plate and into the sockets formed in the bottom rockers. The push-rods should have been marked for refitting in their own places. See that the loose cups are in place in their top ends.

Wipe over the joint face on the cylinder head and clean the corresponding face of the rocker box. Fit a new joint gasket sticking this to the face of the rocker box with a little grease or Gasket Goo jointing compound. (Makers, The Wilcot Parent Co., Fishponds, Bristol.)

Set the piston to top dead centre of compression stroke, found by rotating the crankshaft whilst the fingers are rested on the tops of the push rods and the movement of the piston observed. Turn until the inlet push rod - the one nearer to the cylinder - rises and then falls. As it goes down note the movement of the piston which will begin to rise. Stop when it reaches the top.

The rocker box assembly can now be fitted. Hold it at right angles to the position it occupies on the engine with the rocker cover opening facing the rear. Lift it and place the round push rod opening centrally over the push rods. Pivot the rocker box assembly around this point anti-clockwise into position and bring it down over the head, engaging the tips of the adjustable tappets in the cups of the push rod (loose) ends.

At the same time the two push rod flange studs must be entered into the holes in the cylinder head.

Fit the rocker box bolts and tighten them down evenly, a little at a time, and in sequence, so that the rocker box is pulled down quite square to the face.

Locate the two push rod cover flange gaskets and the guide plate over the flange studs, raise the push rod cover into place over the studs.

Fit the flange stud washers and nuts and tighten up.

Refit the rocker oil drain pipe to the cylinder head and the push rod cover, being careful not to over-tighten and shear off the hollow bolts.

Readjustment of Tappet Clearances. The running clearances quoted are those which must be allowed when the engine is cold.

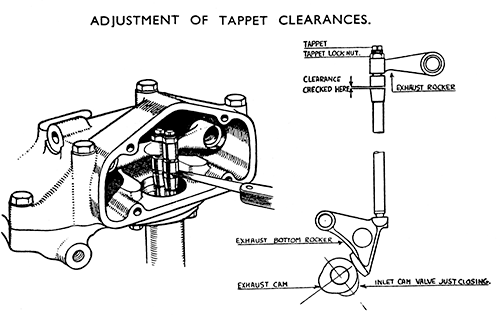

Checking and adjustment must also be carried out when the bearing surface of the bottom rocker is resting on the base of the cam.

Owing to the special profile of the cams which are ground with quietening ramps to take up and restore the running clearances gradually there is only a very limited section of each cam at which the clearance can be set correctly.

The crankshaft must be turned by means of the kickstart until the correct position for dealing with each valve is obtained.

The movement of the rockers should be observed through the opening in the rocker box as the crankshaft is turned forward.

Observe the inlet rocker - that nearer the cylinder - rise and fall and continue turning the crankshaft slowly until the push-rod reaches its lowest point. This is the correct position for checking the exhaust clearance. Illustration above.

Before attending to the inlet clearance turn the crankshaft forward for two thirds of a revolution (240°) until the exhaust rocker is observed to be just about to rise. This is the position for dealing with the inlet tappet adjustment.

The clearances are checked by inserting the feeler gauge between the push rod end (fixed) and the loose ball cup, and are adjusted by slacking back the tappet lock-nut and turning the tappet in the rocker end with the spanner provided. A full turn of the tappet alters the clearance .038" approx.

It is easier to insert the feeler gauge between the loose cup and the push-rod end if the rocker is levered up first to open the gap, and allowed to close on the gauge.

The inlet tappet lock-nut will be more accessible for slackening or tightening if the crankshaft is turned until the inlet rocker is at full lift.

Allow .005" clearance on both push rods.

Note. - Other clearances are employed when checking valve timing. See Service Manual.

After adjustment tighten the lock-nut and recheck in case the adjustment has been altered during the tightening. See illustration page 40.